- UNS: S32760 (F55)

- EN: 1.4501

- DIN: X2CrNiMoCuWN25-7-4

- China: 022Cr25Ni7Mo4WCuN (GB/T 20878) 13

2. Material Properties of S32760

S32760 combines austenitic and ferritic microstructures, delivering superior mechanical and corrosion-resistant performance:

- Chemical Composition:

- Cr: 24–26%, Ni: 6–8%, Mo: 3–4%, N: 0.24–0.32%, Cu: 0.5–1.0% 13

- Mechanical Properties:

- Tensile Strength: ≥550 MPa

- Yield Strength: ≥450 MPa

- Elongation: ≥15%

- Hardness: 200–350 HB 56

- Key Advantages:

- Exceptional Corrosion Resistance: PREn (Pitting Resistance Equivalent) >40, ideal for chloride-rich environments like seawater and chemical processing 16.

- High-Temperature Stability: Retains strength up to 300°C, suitable for heat exchangers and pressure vessels 58.

- Weldability: Compatible with TIG and MIG welding using matching filler metals 68.

3. Standards for S32760 Nuts

S32760 nuts adhere to stringent international specifications:

- Material Standards:

- ASTM A276: Bar and wire specifications 58

- EN 10088-3: Technical delivery conditions 6

- Mechanical Performance Standards:

- ASTM A193 B7M: High-strength bolts/nuts for high-temperature service 78

- ASTM A320 L7M: Low-temperature fasteners for cryogenic applications 7

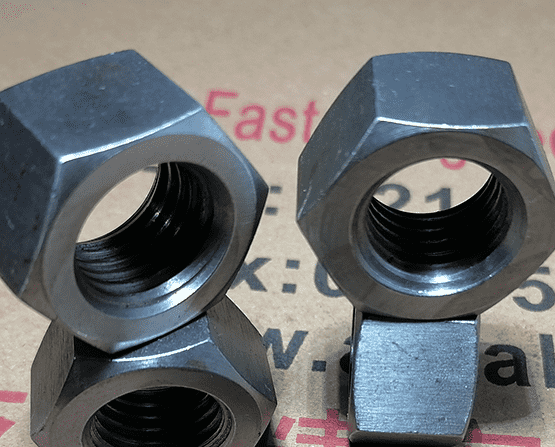

4. Types of Nuts Manufactured with S32760

S32760 is widely used to produce specialized nuts for critical applications:

- Hex Nuts: General-purpose fasteners for offshore platforms and chemical reactors 58.

- Flange Nuts: Sealing solutions for pipelines and subsea equipment 78.

- Lock Nuts: Vibration-resistant designs for marine engines and turbomachinery 57.

- Heavy Hex Nuts: Structural connections in LNG plants and power generation systems 58.

5. Applications of S32760 Nuts

Key Industries:

- Oil & Gas: Subsea wellheads, Christmas trees, and heat exchangers 15.

- Chemical Processing: Acid storage tanks, pumps, and valves 36.

- Marine Engineering: Desalination plants, propeller shafts, and offshore rigs 45.

- Power Generation: Nuclear reactor components and geothermal energy systems 56.

- Primary: S32760 Stainless Steel Nuts, Super Duplex Nuts, UNS S32760 Fasteners

- Secondary: Corrosion-Resistant Hex Nuts, Offshore Grade Nuts, ASTM A193 B7M Nuts

- Long-Tail: S32760 nuts for subsea equipment, S32760 vs 2507 nuts comparison, High-strength duplex steel nuts price

Visual Content (Performance Comparison Table)

| Property | S32760 | 316L | 2507 | |

| Tensile Strength (MPa) | 550–620 | 485–515 | 800–1000 | |

| Corrosion Resistance (PREn) | >40 | 26–32 | >42 | |

| Max Operating Temp (°C) | 300 | 250 | 350 | 56 |

Image Suggestion:

- Alt Text: “S32760 Hex Nuts in Marine Engineering Applications”

- Internal Links:

- “Explore our S32760 flange nuts for subsea pipelines.”

- “Compare S32760 vs 2507 nuts for your project requirements.”

- External Links:

- ASTM Standards: ASTM A276

- Material Datasheet: S32760 Technical Guide

S32760 super duplex nuts excel in harsh environments due to their unmatched strength and corrosion resistance. Ensure compliance with ASTM, EN, or DIN standards for optimal performance 56. For bulk orders or custom specifications, contact us today!