- Key Composition: Chromium (24-26%), Nickel (6-8%), Molybdenum (3-5%), and Nitrogen (0.24-0.32%)12. Minor elements include controlled levels of carbon, silicon, and manganese for optimized performance12.

- Physical Properties: Density (8.03 g/cm³), tensile strength (795 MPa), yield strength (550 MPa), and elongation (15%)2.

Product Performance

S32750 round bars excel in demanding environments due to:

- Superior Corrosion Resistance: Outstanding resistance to pitting, crevice corrosion, and chloride-induced stress corrosion cracking (SCC)14. Ideal for seawater, acidic, and high-chloride environments.

- High Mechanical Strength: Dual-phase microstructure delivers exceptional yield and tensile strength, outperforming standard austenitic steels56.

- Excellent Weldability: Maintains structural integrity post-welding with proper techniques (e.g., TIG, MIG)56.

- Thermal Stability: Retains properties across a wide temperature range (-50°C to 300°C)6.

Production Methods

S32750 round bars are manufactured using advanced processes:

- Hot Rolling: For large-diameter bars (≥20mm), ensuring uniform microstructure and strength7.

- Cold Drawing: Enhances dimensional precision and surface finish for smaller bars7.

- Solution Annealing: Heated to 1020-1100°C followed by rapid cooling to stabilize the austenite-ferrite balance27.

- Forging: Custom shapes and sizes for specialized industrial applications7.

Equivalent Grades

Globally recognized equivalents include:

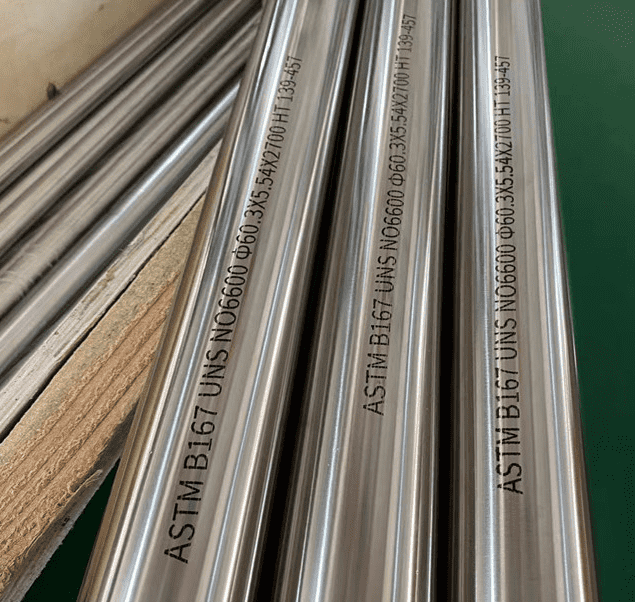

- UNS S32750 (ASTM A182/A479)

- EN 1.4410 (X2CrNiMoN25-7-4)

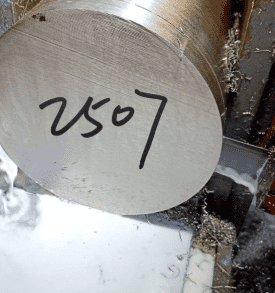

- 2507 (common commercial designation)12.

- China: 022Cr25Ni7Mo4N (GB/T 20878)3.

Application Fields

S32750 round bars are critical in high-performance sectors:

- Oil & Gas: Subsea pipelines, valves, and pump shafts resistant to H₂S and CO₂ corrosion45.

- Chemical Processing: Reactors, heat exchangers, and storage tanks handling aggressive media24.

- Marine Engineering: Desalination plants, offshore platforms, and ship components34.

- Aerospace: High-strength fittings and engine parts2.

- Food & Pharma: Hygienic equipment requiring corrosion resistance and cleanability45.

- Super Duplex Stainless Steel Round Bar

- S32750 Material Properties

- UNS S32750 Equivalent Grades

- High-Strength Corrosion-Resistant Steel

- S32750 Round Bar Applications

- Duplex 2507 vs S32750

- Seawater-Resistant Stainless Steel