A nut is a part that is screwed together with a bolt or a screw for fastening. It is widely used in various mechanical equipment. The nut cooperates with the bolt or the screw through the inner thread to achieve a fastening connection. According to the different materials, nuts can be divided into several types such as carbon steel, stainless steel, and non-ferrous metals.

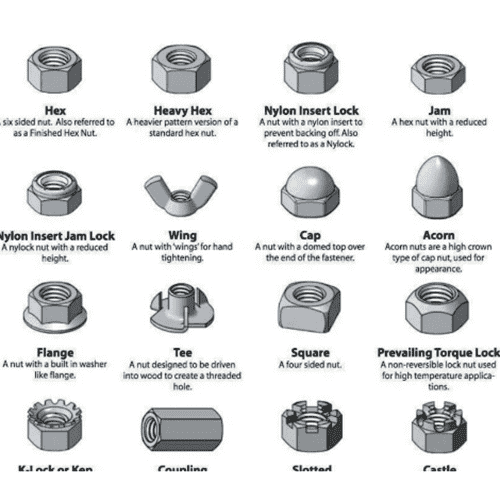

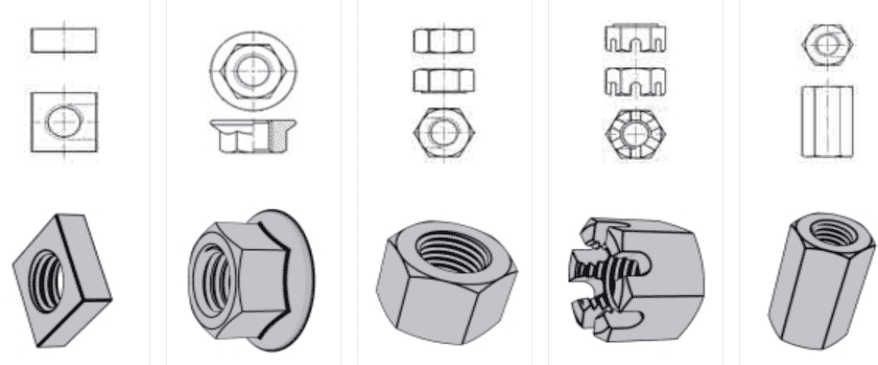

There are many types of nuts, the most common ones are hexagonal nuts, square nuts, flange nuts, nylon nuts, retaining nuts, cap nuts, slotted nuts, and butterfly nuts. Each nut has its specific application scenarios and advantages:

Hexagonal nuts: divided into type I and type II, and type I nuts are divided into three levels: A, B, and C, suitable for occasions with different precision requirements.

| All Material for the nuts: | ||||

| Hastelloy C276 hex nuts | Duplex 2205 hex nut | A193 B8 hex nuts | SS304 hex nuts | Inconel600 hex nuts |

| Hastelloy C22 hex nuts | Duplex S31803 hex nut | B193 B8M hex nuts | SS316 hex nuts | Inconel601 hex nuts |

| Hastelloy C4 hexagonal nut | Super duplex S32750 Nuts | Alloy59 hex nuts | SS316L hex nuts | Incoloy718 hex nuts |

| Monel400 hex nut | Super duplex 2507 nuts | Alloy20 hex nuts | Stainless steel 18-8 hex nuts | Incoloy800H hex nuts |

| Monelk500 hex nut | 904L hex nuts | 309S hex nuts | SS321 hex nuts | Incoloy800 hex nuts |

| Nimonic80A hex nut | Alloy 926 hex nuts -UNS N08926 | 310S hex nuts | 317L hex nuts | Incoloy825 hex nuts |

| A286 Hex nut | S31254 hex nut | 254SMO hex nut | IncoloyA286 Hex nut | |

Square nuts: square in shape, commonly used in industries such as road traffic and home building materials, with good fastening effect.

Flange nuts: with gasket design, with good sealing performance, suitable for occasions such as pipeline connection where an increase in contact surface is required.

Nylon nuts: made of nylon, with insulation, corrosion resistance and other characteristics, suitable for electroplating and communication industries.

Snap nut: Lightweight, commonly used in the aerospace field, used as a secondary nut to prevent the main nut from loosening.

Cap nut: With a cover design to prevent corrosion, suitable for automobiles, tricycles and other parts.

Slotted nut: Used in conjunction with a bolt with a hole to prevent relative rotation, commonly used for connecting mechanical parts.

Butterfly nut: Unique design, easy to hand-tighten, suitable for various fastening occasions.

These different types of nuts can meet the fastening needs of various mechanical equipment and structures, ensuring the firmness and reliability of the connection.