Chemical Composition:

Ni (~69%), Cr (18-21%), Al (1.0-1.8%), Ti (1.8-2.7%), with trace elements like B and Co for enhanced stability37.

Mechanical Properties:

Tensile Strength: 1250 MPa | Yield Strength: 780 MPa | Elongation: 30% (annealed condition)35.

High-Temperature Performance: Maintains structural integrity up to 815°C (1500°F) with minimal creep deformation45.

Physical Properties:

Density: 8.19 g/cm³ | Melting Point: 1405°C | Non-magnetic, ideal for critical electrical applications

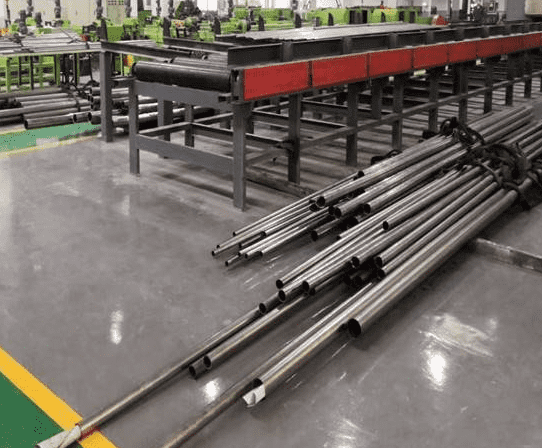

Nimonic 80A round bars are engineered for precision manufacturing in demanding industries:

- Machining:

- Compatible with conventional techniques (turning, milling), but requires low cutting speeds to counteract work hardening38.

- Hot/Cold Working:

- Hot forming: Recommended at 900–1100°C followed by solution annealing (1080°C/air cooling)37.

- Cold forming: Intermediate annealing at 700–750°C to relieve stress67.

- Welding:

- TIG/MIG welding with matching filler metals (e.g., AWS ERNiCr-3); pre-solution treatment minimizes cracking37.

- Heat Treatment:

- Solution annealing (1080°C) + aging (700°C for 16h) to achieve peak hardness and corrosion resistance36.

Industry-Leading Applications

Nimonic 80A dominates sectors requiring unparalleled reliability in extreme conditions:

Aerospace & Defense:

- Turbine blades, rotor disks, and combustion chamber components in jet engines16.

- Critical fasteners and exhaust valves for high-performance aircraft57.

Energy & Nuclear:

- Boiler tube supports in nuclear reactors | High-temperature steam pipelines35.

Automotive & Marine:

- Exhaust valves in racing engines | Corrosion-resistant marine hardware35.

Industrial Manufacturing:

- Dies for precision casting | Heat treatment furnace fixtures67.

Why Partner With Us?

- Certified Excellence: Compliant with UNS N07080, EN 2.4952, and ASTM B637 standards37.

- Custom Solutions: Available in Ø10–300mm diameters, with polished or ground surface finishes.

- Global Support: Fast delivery and technical guidance for bulk orders.

Elevate your projects with Nimonic 80A’s unmatched performance. Contact us today for quotes and material certifications!