Monel product features: Monel 400 is a corrosion-resistant alloy with large dosage, wide application and excellent comprehensive performance. This alloy has excellent corrosion resistance in hydrofluoric acid and fluorine gas media, and also has excellent corrosion resistance to hot concentrated alkali solution. It is also resistant to corrosion by neutral solutions, water, seawater, atmosphere, organic compounds, etc. An important feature of this alloy is that it generally does not produce stress corrosion cracks and has good cutting performance. The structure of Monel 400 alloy is a high-strength single-phase solid solution.

Product corrosion resistance

Monel 400 (N04400) Monel alloy is a corrosion-resistant alloy with the largest usage, the widest application and excellent comprehensive performance. This alloy has excellent corrosion resistance in hydrofluoric acid and fluorine gas media, and also has excellent corrosion resistance to hot concentrated alkali solution. At the same time, it is also resistant to corrosion by neutral solutions, water, seawater, atmosphere, organic compounds, etc. An important feature of this alloy is that it generally does not produce stress corrosion cracks and has good cutting performance.

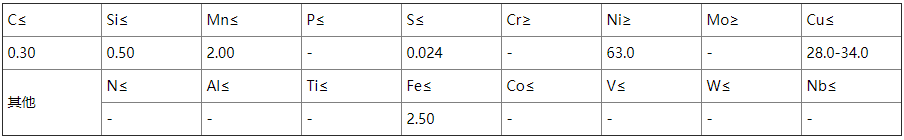

The chemical composition of Monel400 alloy is mainly composed of 30%Cu and 65%Ni plus a small amount of Fe (1%-2%), and the organizational structure is a typical single-phase austenite organization. Since nickel and copper can be mutually soluble in any proportion, there is generally no intermetallic phase precipitation. When observing the organization of this alloy under non-etching conditions under a metallographic microscope, it can be seen that there are very dispersed non-metallic inclusions on the austenite matrix, such as sulfides and silicates. Under certain conditions, carbides can also be observed. Due to the difference in chemical composition, it can have a variety of alloy grades, but there is no significant difference in corrosion resistance between them. Monel400 alloy is more resistant to corrosion in reducing media than pure nickel, and more resistant to corrosion in oxidizing media than pure copper.

Corrosion resistance of Monel 400 (N04400):

- Monel’s corrosion resistance is generally superior to that of nickel copper. It is more resistant to reducing media than pure nickel and more resistant to oxidizing media than pure copper. It has excellent corrosion resistance to sulfuric acid, phosphoric acid, and carbon. It is especially resistant to hydrochloric acid and has excellent corrosion resistance to hot concentrated alkali. Monel 400 alloy has excellent corrosion resistance in fluorine gas, hydrochloric acid, sulfuric acid, hydrofluoric acid, and their derivatives.

At the same time, it is more corrosion resistant than copper-based alloys in seawater. Monel 400 is a deformable nickel-copper nickel-based alloy with good seawater corrosion resistance and chemical corrosion resistance, and strong resistance to chloride stress corrosion cracking. This alloy is one of the few alloys that can be used in fluorides. It has good resistance to oxide stress cracking corrosion in hydrofluoric acid and fluorine gas media, such as seawater and salt water environments. Monel 400 also has very good corrosion resistance in moderately concentrated alkaline and salt solutions. In a cold alkaline environment, the alloy is used in weak acid environments such as sulfur and hydrogen fluoride.

- Acid medium: Monel400 is corrosion-resistant in sulfuric acid with a concentration of less than 85%. Monel400 is one of the few important materials that can resist hydrofluoric acid.

- Water corrosion: Monel400 alloy has excellent corrosion resistance in most water corrosion conditions, and pitting corrosion and stress corrosion are rarely found, and the corrosion rate is less than 0.025mm/a.

- High temperature corrosion: The maximum temperature of Monel400 working continuously in air is generally around 600℃, and the corrosion rate is less than 0.026mm/a in high-temperature steam. Ammonia: Due to the high nickel content of Monel400 alloy, it can resist corrosion under anhydrous ammonia and ammoniation conditions below 585℃.