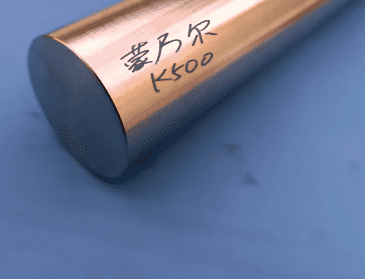

Key Properties of MONEL K500 Round Bar

- High Strength: Tensile strength up to 1,034 MPa and yield strength of 690 MPa after aging treatment, making it suitable for high-stress components35.

- Outstanding Corrosion Resistance: Resists seawater, acids, and chlorides, outperforming most stainless steels in marine and chemical environments14.

- Heat Resistance: Maintains mechanical stability up to 1,350°C, ideal for high-temperature applications45.

- Excellent Machinability: Can be forged, welded, and machined using conventional methods despite its high hardness (~450 HV)23.

- Non-Magnetic: Perfect for aerospace and electronic components requiring non-magnetic properties17.

Machining and Processing Methods

MONEL K500 round bars require specialized techniques to optimize performance:

- Heat Treatment:

- Solution Annealing: Heat to 1,000–1,050°C followed by rapid cooling to enhance ductility35.

- Aging Treatment: Temper at 480–520°C for 1–2 hours to achieve peak strength35.

- Forming: Suitable for hot/cold forging and rolling to produce rods, plates, or custom shapes24.

- Welding: Compatible with TIG, MIG, and resistance welding; post-weld aging recommended57.

- Surface Treatment: Polishing or coatings to enhance wear resistance in abrasive environments5.

Applications of MONEL K500 Round Bar

MONEL K500 is indispensable in industries requiring reliability under harsh conditions:

- Marine Engineering: Pump shafts, valve seals, and offshore platform components15.

- Oil & Gas: Drill collars, valve stems, and subsea equipment resistant to sour gas15.

- Chemical Processing: Reactors, heat exchangers, and acid-handling pumps27.

- Aerospace: Non-magnetic fasteners, engine components, and landing gear parts57.

- Nuclear Power: Control rod mechanisms and reactor core fixtures5.

Products Made from MONEL K500 Round Bar

This alloy is processed into precision components such as:

- Shafts & Fasteners: High-strength bolts, drive shafts, and studs15.

- Valve Components: Seals, stems, and trim parts for corrosive fluid control17.

- Pump Parts: Impellers, sleeves, and bearings resistant to cavitation15.

- Marine Hardware: Propeller shafts, seawater piping, and fittings47.

- MONEL K500 Round Bar Supplier

- High-Strength Nickel Alloy Rod

- Corrosion-Resistant Alloy Round Bar

- Machinable MONEL K500 Bar

- Marine Grade Nickel Alloy Components

- Aerospace Alloy Round Bar

- Heat-Treated MONEL K500 Rod

Why Choose MONEL K500 Round Bar?

Combining unmatched corrosion resistance, mechanical strength, and adaptability, MONEL K500 is the go-to material for industries pushing the limits of performance. Whether for marine, aerospace, or energy sectors, this alloy ensures longevity and reliability.

Contact us today for customized MONEL K500 solutions tailored to your needs!