Material Properties

Chemical Composition (wt%)

| Ni 63–70 | Cu 28–34 | Fe ≤2.5 | Mn ≤2.0 | Si ≤0.5 | C ≤0.3 | S ≤0.024 | 34.

Mechanical Properties

- Tensile Strength: 480–750 MPa | Yield Strength: 170–345 MPa | Elongation: 20–40% 34.

- Hardness: 135–200 HB (Brinell) | Density: 8.83 g/cm³ | Melting Point: 1300–1390°C 34.

Key Performance Features

- Superior resistance to seawater, hydrochloric acid, sulfuric acid, and chloride-induced stress corrosion cracking 23.

- Excellent performance in high-temperature environments up to 537°C (1000°F) 45.

- Maintains ductility and strength in both oxidizing and reducing conditions 23.

3. Standards and Specifications

Monel 400 nuts comply with:

- ASTM B164/B164M: Standard for nickel-copper alloy rods, bars, and forgings 13.

- ASME SB164: Equivalent specifications for pressure vessel components 16.

- DIN 934/936: Metric hex nuts and flange nuts 36.

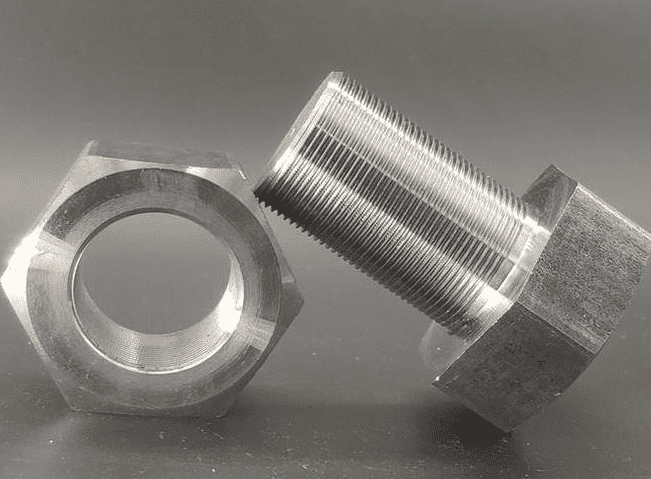

4. Types of Nuts Produced with Monel 400

- Hex Nuts (ASTM A194 compliant)

- Flange Nuts (SAE J995 standard)

- Lock Nuts (e.g., all-metal prevailing torque or Nylock variants)

- Cap Nuts for corrosion-resistant sealing in marine or chemical systems 13.

5. Key Applications

Marine & Offshore

- Seawater pumps, propeller shafts, and subsea fasteners exposed to saltwater corrosion 25.

Chemical & Petrochemical

- Reactors, heat exchangers, and pipelines handling sulfuric acid, hydrochloric acid, and chlorides 23.

Oil & Gas

- Valves, drilling equipment, and components in sour gas environments 34.

Aerospace

- Fuel system components and fasteners requiring high-temperature stability 35.

Primary Keywords:

- Monel 400 Nuts

- UNS N04400 Fasteners

- Marine-Grade Nickel-Copper Alloy Nuts

- ASTM B164 Monel 400 Nuts

Long-Tail Keywords:

- “Monel 400 Hex Nuts for Seawater Systems”

- “Corrosion-Resistant Monel 400 Flange Nuts”

- “High-Temperature Monel 400 Lock Nuts”

Suggested Tables

Table 1: Chemical Composition of Monel 400

| Element | Ni | Cu | Fe | Mn | Si | C | |

| wt% | 63–70 | 28–34 | ≤2.5 | ≤2.0 | ≤0.5 | ≤0.3 | 34. |

Table 2: Mechanical Properties

| Tensile Strength | Yield Strength | Elongation | Hardness | |

| 480–750 MPa | 170–345 MPa | 20–40% | 135–200 HB | 34. |

Conclusion

Monel 400 nuts are indispensable in industries requiring extreme corrosion resistance, high-temperature stability, and durability in harsh environments. Compliant with ASTM, ASME, and DIN standards, they are widely used in marine, chemical, oil and gas, and aerospace applications.

Monel 400 nuts, UNS N04400 fasteners, marine-grade nickel alloy nuts, ASTM B164 Monel 400.

“Monel 400 nuts for seawater and chemical systems.”(e.g., “Monel 400 bolts” or “nickel-copper alloy washers”) and add alt-text for tables (e.g., “Monel 400 nut corrosion resistance data”).