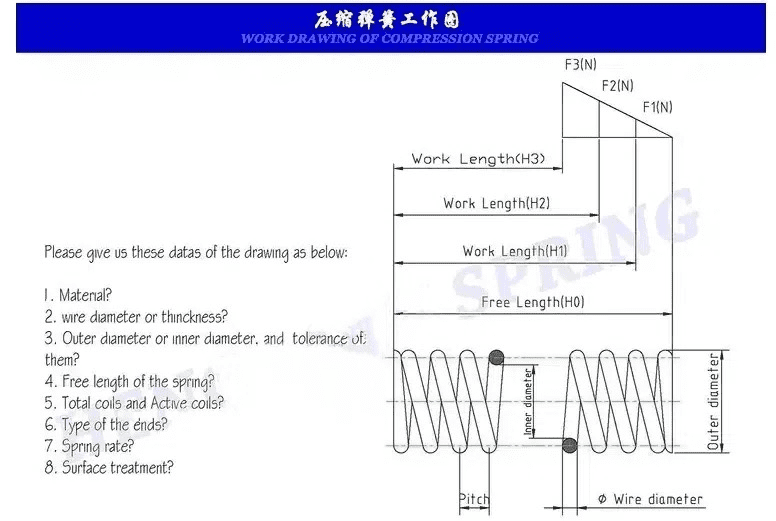

Since the spring is not a standard part,Therefore, customers need to provide some basic information when sent inquiries, such as spring type, material, wire diameter, spring outer diameter, free length, number of turns, force requirements, hardness, fatigue life, etc. Attached is the information that needs to be provided when making a spring inquiry:

| High temperature

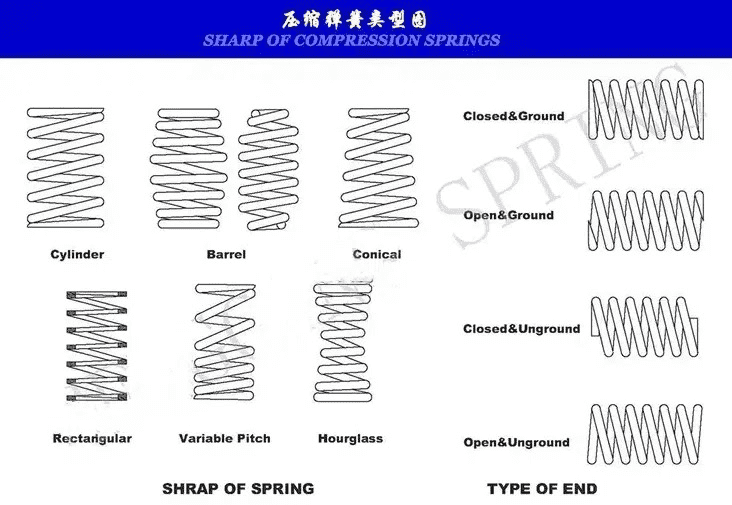

Springs type |

Compression springs, tension springs, torsion springs, mold springs, disc springs, scroll springs, constant force springs, wave springs, special-shaped springs, etc. |

| Material | Carbon steel:70\72A\72B\82B\进口琴钢丝\T9A\SWPB\WPC\65Mn |

| Common alloy steel

:60Si2MnA\50CrVA\55CrSiA\60CrMnA\60Cr2VA SWOSC\SEA9254\SEA9260 |

|

| Stainless steel:SUS302\SUS304\SUS316\SUS631\17-7PH | |

| High temperature alloy :30W4Cr2VA\Inconel X750 \ Inconel 718\ Nimonic90 / Incoloy A-286-400-500℃ | |

| end style

(hook and loop style) |

Grinding tightly, grinding tightly without grinding, grinding without grinding, circular shackles with center pressing, off-circle shackles, semi-circular shackles, etc. See the spring end (shackle) style diagram for details. |

| Material range | Wire diameter φ0.3-80 mm;Plate thickness δ0.1-25mm |

| Number of turns | Left-hand/right-hand rotation, generally the default is right-hand rotation; effective turns, total number of turns, etc. |

| Force requirements | Attached spring drawing style |

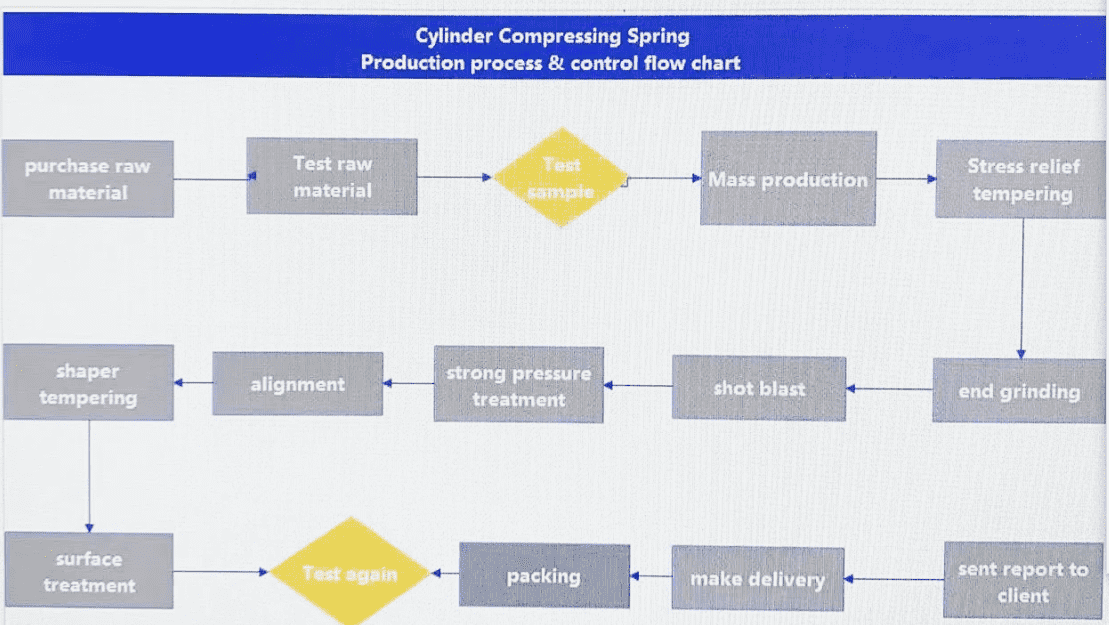

| Special requirements | Fatigue life, high temperature resistance, strong pressure and constant temperature treatment, corrosion resistance requirements, etc. |

| Surface treatment | Galvanizing, chrome plating, nickel plating, electrophoresis, spray painting, plastic spraying, blackening, oiling, Dacromet, etc. |

| Packing | Inner packaging: PVC bag or bubble film; outer packaging: carton, woven bag or pallet. |

| Quality | ISO9001-2015 |

| Quantity | Customer inquiry provides quantity requirements, large quantity will give priority |

| Delivery way | Express delivery, logistics or other transportation methods negotiated by both parties |