Material Properties

Chemical Composition:

- Nickel (Ni): 50–55%

- Chromium (Cr): 17–21%

- Iron (Fe): 15–20%

- Niobium (Nb): 4.75–5.5%

- Molybdenum (Mo): 2.8–3.3%

- Titanium (Ti): 0.65–1.15%12.

Mechanical Properties:

- Tensile Strength: 1,275 MPa (room temperature) | 1,100 MPa (650°C)25.

- Yield Strength: 1,034 MPa (room temperature) | 890 MPa (650°C)25.

- Elongation: ≥12% (room temperature)5.

- Hardness: ≥36 HRC25.

Performance Advantages:

- High-Temperature Resistance: Retains mechanical integrity up to 700°C (1,292°F)24.

- Corrosion Resistance: Excellent resistance to chloride stress corrosion cracking (SCC), hydrogen sulfide (H₂S), and sulfuric acid23.

- Oxidation Stability: Forms a protective oxide layer in extreme thermal cycling34.

3. Standards & Certifications

Inconel 718 nuts adhere to global standards for quality assurance:

- ASTM: B637 (bars/rods), B564 (forgings)15.

- EN: 2.4668 (Europe)3.

- ISO: 9917 (international)1.

- Others: AMS 5599 (aerospace), NACE MR0175 (sour gas environments)23.

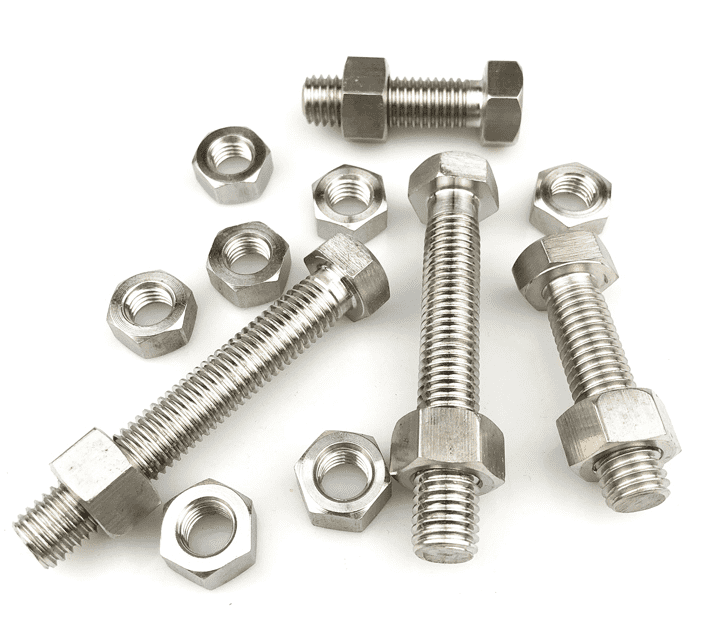

4. Types of Nuts Produced with Inconel 718

The alloy is widely used to manufacture precision nuts for critical applications:

- Hex Nuts (ASME B18.2.2)

- Heavy Hex Nuts (ASME B18.2.6)

- Flange Nuts (ASTM A194)

- Lock Nuts (DIN 985/982)56.

5. Application Fields

Inconel 718 nuts are essential in industries demanding uncompromising reliability:

- Aerospace: Turbine blades, combustion chambers, and rocket engine components23.

- Oil & Gas: Subsea drilling tools, sour gas wellheads, and refinery pipelines24.

- Nuclear Energy: Reactor core fasteners and steam generator parts34.

- Chemical Processing: Heat exchangers, reactors, and sulfuric acid systems12.

- Primary:

Inconel 718 Nuts, UNS N07718 Fasteners, EN 2.4668 Nuts, High-Temperature Alloy 718 Nuts. - Long-Tail:

Inconel 718 Hex Nuts for Aerospace, Corrosion-Resistant 718 Nuts Supplier, Nuclear-Grade Alloy 718 Lock Nuts. - Regional:

Inconel 718 Nuts USA, EN 2.4668 Nuts Europe, GH4169 Nuts China.

7. Technical Data Table

| Property | Value | Source |

| Tensile Strength | 1,275 MPa (RT) | 25 |

| Yield Strength | 1,034 MPa (RT) | 25 |

| Operating Temperature | Up to 700°C (1,292°F) | 24 |

| Corrosion Resistance | Excellent (Cl⁻, H₂S, acids) | 23 |

Why Choose Inconel 718 Nuts?

Inconel 718 outperforms conventional stainless steel and titanium alloys in high-stress, corrosive, and thermal environments24. Its γ” (Ni₃Nb) precipitation-hardened structure ensures longevity in aerospace, nuclear, and oilfield applications34.

- Internal Linking: Use anchor text like “Explore Inconel 718 Bolts” or “Learn about ASTM B637 Standards.”56.

- Image Alt Text: Inconel-718-Nuts-Aerospace.jpg– “High-strength Alloy 718 nuts in turbine assemblies.”25.

“Discover Inconel 718 nuts (UNS N07718/EN 2.4668) – engineered for aerospace, oil & gas, and nuclear industries. Exceptional strength, corrosion resistance, and compliance with ASTM/EN/ISO standards. Request a quote now!”