Its composition includes:

- Nickel (Ni): 58-63% (ensures corrosion resistance and thermal stability) 12

- Chromium (Cr): 21-25% (forms protective Cr₂O₃ oxide layer for oxidation resistance) 23

- Aluminum (Al): 1.0-1.7% (enhances high-temperature strength via Al₂O₃ formation) 12

- Iron (Fe): Balances mechanical properties and cost-effectiveness 13

Outstanding Product Performance

Extreme Temperature Resistance:

- Maintains structural integrity up to 1200°C (2192°F) with exceptional oxidation resistance 23.

- Retains tensile strength (≥650 MPa) and yield strength (≥310 MPa) at elevated temperatures 12.

Corrosion Resistance:

- Resists carburization, sulfur-based atmospheres, and stress corrosion cracking (SCC) 13.

Mechanical Stability:

- High creep rupture strength (>500°C) and elongation (≥30%) ensure durability under cyclic thermal loads 23.

Fabrication Flexibility:

- Weldable via TIG/MIG methods and compatible with cold/hot forming processes 23.

Production Methods

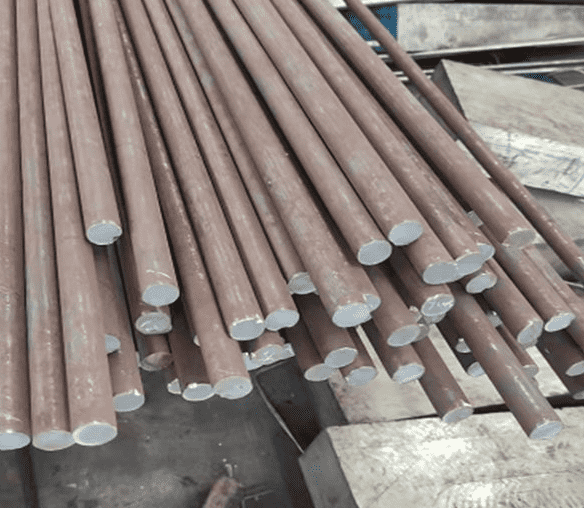

Inconel 601 round bars are manufactured through:

- Melting & Casting:

- Vacuum induction melting (VIM) or electric arc furnaces ensure low impurity levels 13.

- Hot Working:

- Hot rolled/forged at 980-1200°C (1796-2192°F) to achieve uniform grain structure 23.

- Heat Treatment:

- Solution annealing at 1095-1150°C (2003-2102°F) followed by rapid cooling 12.

- Surface Finishing:

- Cold drawing, grinding, or acid pickling to meet dimensional tolerances and surface quality 13.

Similar Grades

- UNS N06601 (USA), 4851 (DIN), NS3101 (China), NCF601 (Japan) 12.

Application Fields

Inconel 601 round bars are critical in:

- Aerospace: Combustors, exhaust systems, and gas turbine components 34.

- Chemical Processing: Heat exchangers, reactor vessels, and catalytic grids 13.

- Heat Treatment: Furnace trays, radiant tubes, and annealing equipment 13.

- Energy & Power: Nuclear reactor parts, boiler systems, and waste incineration chambers 25.

- Automotive: Turbocharger housings and exhaust manifolds 2.

- Inconel 601 Round Bar

- UNS N06601 Nickel Alloy Rod

- High-Temperature Inconel 601 Supplier

- Aerospace-Grade 2.4851 Alloy

- Corrosion-Resistant Inconel 601 Stock

Certified suppliers offer Inconel 601 round bars in diameters from 5mm to 300mm, compliant with ASTM B166, AMS 5666, and EN 10095 standards 13.

Optimized for search engines with keywords: Inconel 601 round bar, UNS N06601 alloy, high-temperature nickel alloy, aerospace-grade rods, corrosion-resistant Inconel 601.