Key composition includes

- Nickel (Ni): ~72%

- Chromium (Cr): 14–17%

- Iron (Fe): 6–10%

- Other Elements: Aluminum (Al ≤0.35%), Titanium (Ti ≤0.50%), Copper (Cu ≤0.5%), and trace amounts of carbon (C ≤0.15%) and manganese (Mn ≤1.0%).

Physical & Mechanical Properties34:

- Density: 8.4 g/cm³

- Melting Range: 1,315–1,370°C

- Tensile Strength (Room Temp): ~620 MPa

- Yield Strength (Room Temp): ~250 MPa

- Elongation: ~40%

- Hardness: ≤160 HB

Product Performance Highlights

Superior High-Temperature Stability:

- Maintains excellent oxidation resistance and mechanical strength up to 700°C, with proven stability in continuous service at 1,100°C12.

- Resists thermal fatigue and creep deformation in extreme heat5.

Outstanding Corrosion Resistance:

- Resists chloride stress corrosion cracking, organic acids (acetic, formic), and nuclear-grade high-purity water23.

- Performs exceptionally in both oxidizing and reducing atmospheres35.

Excellent Fabricability:

- Easily welded via TIG, MIG, or resistance welding methods; post-weld annealing (870°C/1h) eliminates stress36.

- Suitable for cold/hot working, forging, and machining into complex shapes13.

Production Methods

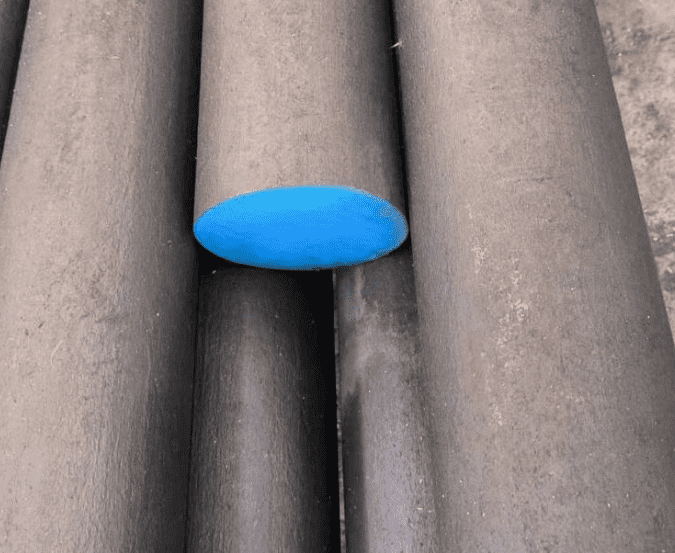

Inconel 600 round bars are manufactured through precision processes36:

- Vacuum Induction Melting (VIM):

- High-purity raw materials are melted under controlled conditions to minimize impurities.

- Hot Rolling & Forging:

- Ingots are hot-rolled or forged into billets to refine grain structure and enhance mechanical properties.

- Cold Drawing/Finishing:

- Cold-drawn to achieve tight dimensional tolerances and smooth surface finishes.

- Solution Annealing:

- Heated to 1,050–1,100°C and rapidly cooled to optimize corrosion resistance and ductility.

Equivalent Grades & Standards

- UNS N06600

- ASTM B168, AMS 5540, DIN 2.4816

- GH600 (China), NC15Fe (France), NiCr15Fe (ISO)23

Key Application Fields

Inconel 600 round bars are indispensable in industries requiring extreme reliability25:

- Aerospace & Gas Turbines:

- Combustion chambers, turbine blades, and exhaust systems.

- Chemical Processing:

- Reactors, heat exchangers, and piping for sulfuric/nitric acid environments.

- Nuclear Energy:

- Reactor core components, fuel rod cladding, and steam generator tubes.

- Oil & Gas:

- Downhole tools, valves, and components exposed to sour gas.

- Power Generation:

- Boiler tubes, superheater components, and pollution control systems.

- Inconel 600 Round Bar Supplier

- UNS N06600 High-Temperature Alloy

- Nickel-Chromium Round Bar for Aerospace

- ASTM B168 Inconel 600 Applications

- Corrosion-Resistant Inconel 600 Rod

- Nuclear-Grade Inconel 600 Properties

- Inconel 600 vs Hastelloy C276

Inconel 600 round bars deliver unmatched performance in high-temperature and corrosive environments, making them a cornerstone material for critical industrial applications. For custom specifications or bulk orders, partner with certified suppliers specializing in advanced nickel alloys.