Performance characteristics

- **Excellent corrosion resistance**: Incoloy 926 alloy has good resistance to chloride stress corrosion cracking (SCC) and pitting, and is particularly suitable for harsh environments containing chloride ions. Its corrosion resistance is due to its high content of chromium and molybdenum. The combination of these two elements forms a strong protective film on the surface of the alloy, which effectively prevents oxidation and corrosion.

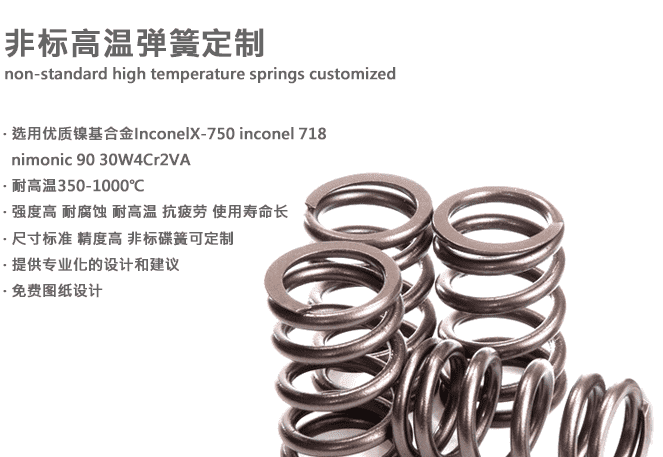

- **Good high temperature resistance**: Incoloy 926 can maintain excellent mechanical properties in high temperature environments and can resist oxidation and sulfidation corrosion. Its operating temperature range is usually between -200°C and 1000°C. It is stable at high temperatures and is suitable for applications with high temperature steam and gas flow.

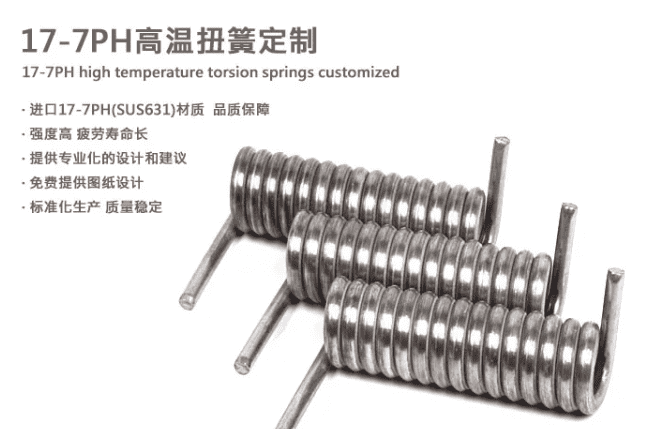

- **Good mechanical properties**: Incoloy 926 alloy has high tensile strength and yield strength, and can maintain good toughness and strength at high temperatures. This allows it to maintain structural integrity in high temperature, high stress and corrosive environments.

- **Oxidation resistance**: Due to the high chromium content in the alloy, it has very good oxidation resistance and can be used for a long time in an oxidizing environment without losing its mechanical properties.

- **Resistance to sulfidation and chlorination corrosion**: Compared with many stainless steels and other alloy materials, Incoloy 926 is more durable in sulfidation and chlorination environments. This makes it particularly suitable for use in chemical processing equipment, especially in environments with acidic or sulfiding atmospheres.

Main Applications

Due to its unique properties, Incoloy 926 alloy is widely used in fields that require high strength, high corrosion resistance and high temperature performance. Specific applications include:

– **Chemical and petrochemical industries**: In chloride environments, high-temperature corrosive gases and chemically corrosive liquid environments, Incoloy 926 alloy is used to manufacture reactors, heat exchangers, pumps, valves, pipelines and other equipment.

– **Power industry**: In high-temperature, corrosive gas or steam environments, especially in power plant boilers, exhaust gas emission systems and other components, Incoloy 926 provides reliable high temperature and corrosion protection.

– **Marine engineering**: Incoloy 926 has excellent corrosion resistance in seawater environments and is often used in marine equipment such as offshore platforms, ship components, etc.

– **Food and pharmaceutical industries**: Due to its good corrosion resistance and chemical stability, Incoloy 926 is also used in food processing and pharmaceutical equipment, especially those processes involving high-temperature steam or acidic chemicals.