Incoloy 825 Chemical component:

| Alloy | % | Ni | Cr | Fe | C | Mn | Si | Cu | Mo | Al | Ti | P | S |

| 825 | Min | 38 | 19.5 | balance | – | – | – | 1.5 | 2.5 | – | 0.6 | – | – |

| Max | 46 | 23.5 | 0.05 | 1 | 0.5 | 3 | 3.5 | 0.2 | 1.2 | 0.03 | 0.03 |

Incoloy 825 alloy has the following characteristics:

- Good resistance to stress corrosion cracking

- Good resistance to pitting and crevice corrosion

- Good resistance to oxidation and non-oxidizing hot acid

- Good mechanical properties at room temperature and high temperature up to 550℃

- Certified for manufacturing pressure vessels with a temperature of up to 450℃ [1]

Corrosion resistance of Incoloy 825 alloy:

825 alloy is a general engineering alloy that has resistance to acid and alkali metal corrosion in both oxidizing and reducing environments. The high nickel content makes the alloy effectively resistant to stress corrosion cracking. It has good corrosion resistance in various media, such as sulfuric acid, phosphoric acid, nitric acid and organic acids, alkali metals such as sodium hydroxide, potassium hydroxide and hydrochloric acid solutions. The high comprehensive performance of 825 alloy is reflected in nuclear combustion dissolvers with a variety of corrosive media, such as sulfuric acid, nitric acid and sodium hydroxide are all processed in the same equipment.

Incoloy 825 alloy application range application areas are:

825 alloy is widely used in various industrial fields with a service temperature not exceeding 550℃.

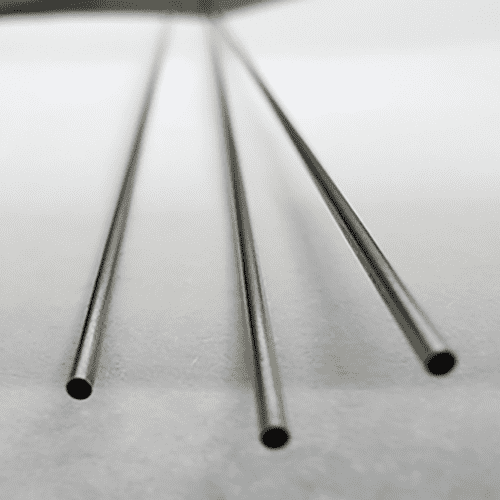

Application areas of Incoloy 825 alloy: Heating tubes, containers, baskets and chains used in sulfuric acid pickling plants, seawater cooling heat exchangers, marine product pipeline systems, acidic gas environment pipelines, heat exchangers, evaporators, washing and immersion tubes in phosphoric acid production, air heat exchangers in petroleum refining, food engineering chemical processes, flame retardant alloys for high-pressure oxygen applications