- Chemical Composition:

- Ni (24.0–27.0%), Cr (13.5–16.0%), Fe (balance), with Mo (1.0–1.5%), Ti (1.9–2.35%), and Al (≤0.35%) for enhanced stability35.

- Mechanical Properties:

- High-Temperature Strength: Tensile strength up to 1250 MPa, yield strength 650–800 MPa at 650°C12.

- Oxidation Resistance: Forms a protective Cr₂O₃ layer, effective up to 1300°F (704°C)13.

- Creep Resistance: Maintains structural integrity under prolonged stress at elevated temperatures25.

- Heat Treatment:

- Solution annealing at 980–1000°C followed by aging at 700–720°C to achieve peak hardness and stress rupture resistance56.

Advanced Processing Capabilities

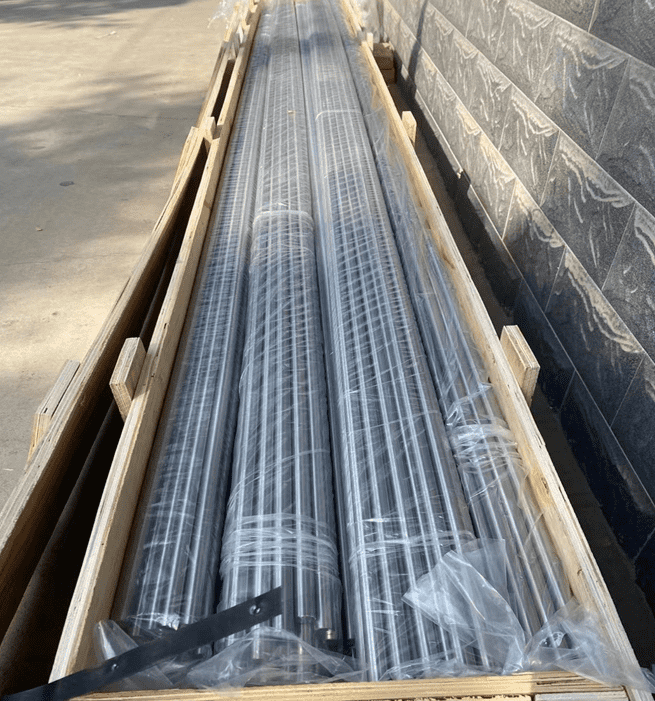

Incoloy A-286 round bars are engineered for precision manufacturing:

- Hot Working: Forge at 900–1140°C with post-process annealing to refine grain structure26.

- Cold Working: Intermediate annealing at 700–750°C required to relieve stress during forming23.

- Welding: Compatible with TIG/MIG methods using AWS ERNiCr-3 filler; pre-solution treatment minimizes cracking26.

- Machining: Use carbide tools with low cutting speeds to counteract work hardening25.

Critical Industry Applications

Incoloy A-286 excels in demanding sectors:

Aerospace & Defense:

- Turbine disks, rotor blades, and jet engine fasteners operating below 650°C12.

Energy & Nuclear:

- Nuclear reactor fuel rod supports, high-pressure steam pipelines (>800°C)45.

Automotive:

- Turbocharger components, exhaust valves, and racing engine parts46.

Petrochemical:

- Reactors, heat exchangers, and corrosion-resistant piping in aggressive chemical environments34.

Why Choose Our Incoloy A-286 Round Bars?

- Certified Quality: Compliant with ASTM A638, AMS 5726, and UNS S66286 standards35.

- Custom Solutions: Available in Ø10–300mm diameters, with polished or ground finishes37.

Global Supply Chain: Fast delivery for bulk orders, backed by