Key properties include:

- High-Temperature Stability: Maintains mechanical strength up to 550°C, ideal for thermal cycling environments34.

- Corrosion Resistance: Resists sulfuric acid, phosphoric acid, chlorides, and seawater due to its 38-46% nickel and 19.5-23.5% chromium content12.

- Stress Corrosion Cracking (SCC) Resistance: Performs reliably in chloride-rich and acidic conditions37.

- Physical Properties: Density of 8.14 g/cm³, melting point of 1370-1400°C, and tensile strength of 550-750 MPa46.

Standards for Incoloy 825 Nuts

Incoloy 825 nuts comply with globally recognized standards for quality and safety:

- ASTM/ASME: ASTM B424 (plate), ASTM B425 (bar), ASTM B564 (forgings)56.

- UNS Designation: UNS N0882535.

- DIN: 2.485837.

- ISO: ISO 4033 (hex nuts) and ISO 3506 (corrosion-resistant fasteners)6.

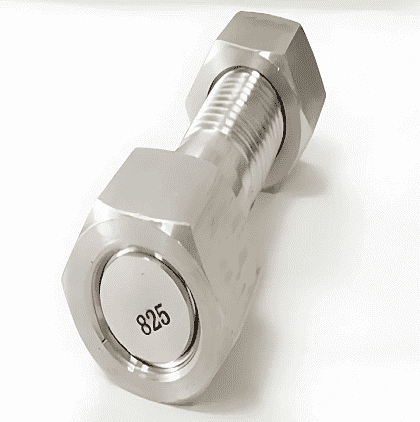

Types of Nuts Manufactured with Incoloy 825

Incoloy 825’s versatility supports production of:

- Hex Nuts: Standard ISO 4033-compliant nuts for general industrial use6.

- Lock Nuts: Vibration-resistant designs for aerospace and marine applications78.

- Flange Nuts: Used in high-pressure pipelines and chemical reactors37.

- Heavy Hex Nuts: For structural applications requiring high load-bearing capacity8.

Key Applications of Incoloy 825 Nuts

- Oil & Gas: Subsea wellhead equipment, pipelines, and sour gas processing systems18.

- Chemical Processing: Reactors, heat exchangers, and acid-handling systems26.

- Marine Engineering: Offshore platforms, desalination plants, and seawater-cooled heat exchangers67.

- Aerospace: Jet engine fasteners exposed to extreme temperatures and fuels34.

- Nuclear Energy: Radiation-resistant components in reactor cooling systems38.

Incorporate these high-value keywords to enhance search visibility:

- Incoloy 825 nuts

- High-temperature alloy nuts

- Corrosion-resistant fasteners

- ASTM B425 Incoloy 825 hex nuts

- UNS N08825 marine fasteners

- Incoloy 825 lock nuts for aerospace

- Oil & gas industry superalloy nuts

- ISO 4033 Incoloy 825 nuts

Suggested Visuals for Enhanced Engagement

- Temperature vs. Strength Curve: Compare Incoloy 825’s performance at 20°C to 550°C34.

- Corrosion Rate Comparison Table: Rank Incoloy 825 against stainless steel 316 in sulfuric acid and seawater26.

- Application Distribution Chart: Highlight usage in oil & gas (35%), chemical (30%), marine (20%), and aerospace (15%) sectors67.

Why Incoloy 825 Nuts Excel in Harsh Environments

Incoloy 825’s optimized composition (Ni-Cr-Mo-Cu-Ti) ensures durability in aggressive media like sulfuric acid, chlorides, and high-pressure steam13. Its compliance with ASTM, ISO, and DIN standards guarantees reliability across industries56.

Conclusion

Incoloy 825 nuts are critical for industries demanding corrosion resistance, thermal stability, and mechanical strength. By targeting keywords like “Incoloy 825 marine fasteners” or “ASTM B425 nuts,” this content aligns with search intent while providing actionable insights for engineers and procurement teams.