Its composition includes:

-

- Nickel (Ni): ~64% (base metal)1

- Chromium (Cr): 14–17.5%13

- Molybdenum (Mo): 14–17%13

- Low carbon (C): ≤0.009% to minimize carbide precipitation34.

Similar Grades:

- UNS N06455 (USA), NS3203 (China), 2.4610 (DIN/Germany)34.

Key Properties

Exceptional Corrosion Resistance:

- Resists sulfuric acid, hydrochloric acid, nitric acid, and chloride-induced stress corrosion cracking (SCC)15.

- Maintains integrity in temperatures up to 1040°C with outstanding oxidation resistance36.

High-Temperature Strength:

- Tensile strength: 690 MPa; Yield strength: 276 MPa; Elongation: 40% at room temperature16.

- Retains mechanical stability in 650–1040°C ranges, ideal for thermal cycling applications34.

Weldability & Fabrication:

- Compatible with TIG, MIG, and plasma arc welding; minimal risk of sensitization in heat-affected zones (HAZ)34.

- Requires solution annealing (1025–1125°C) and rapid cooling post-processing to preserve microstructure24.

Production Methods

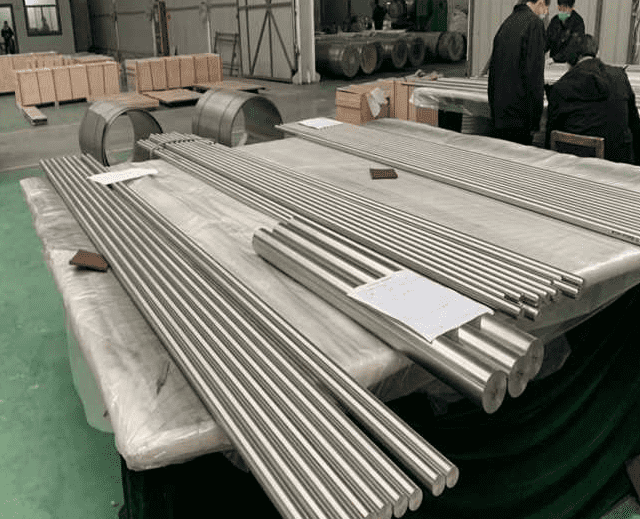

Hastelloy C4 round bars are manufactured via:

- Vacuum Induction Melting (VIM): Ensures precise control over alloy purity24.

- Hot/Cold Working:

- Hot forging at 1080–900°C followed by water quenching2.

- Cold rolling with intermediate annealing for precision dimensions24.

- Heat Treatment:

- Solution annealing at 1025–1125°C + water quenching26.

- Final grinding/polishing for surface finish and dimensional accuracy2.

Applications in Demanding Industries

Hastelloy C4 round bars are critical for:

- Chemical Processing: Reactors, heat exchangers, and acid storage tanks17.

- Oil & Gas: Downhole tools, sour gas pipelines, and valves17.

- Aerospace: Jet engine components and fuel system parts14.

- Power Generation: Flue gas scrubbers and boiler systems46.

Enhance visibility with Google AdWords-friendly terms:

- Hastelloy C4 Round Bar

- Nickel-Chromium-Molybdenum Alloy Supplier

- Corrosion-Resistant UNS N06455 Bars

- High-Temperature Hastelloy C4 Rods

- NS3203/2.4610 Alloy Stock

Certified suppliers offer Hastelloy C4 round bars in diameters 6–300mm, compliant with ASTM B574, DIN 17752, and NACE MR0175 standards24.