Key Properties:

Chemical Composition:

- Nickel (Ni): ≥56%

- Chromium (Cr): 20–22.5%

- Molybdenum (Mo): 12.5–14.5%

- Tungsten (W): 2.5–3.5%

- Iron (Fe): 2–6%12.

Mechanical Properties:

- Tensile Strength: 690–760 MPa

- Yield Strength: 310–350 MPa

- Elongation: ≥40%

- Hardness: 95–100 HRB25.

Performance Advantages:

- Extreme Corrosion Resistance: Excels in chloride-rich, sulfuric acid, and hydrogen fluoride environments14.

- High-Temperature Stability: Maintains integrity up to 600°C (1112°F)56.

- Versatility: Resists pitting, crevice corrosion, and stress corrosion cracking (SCC)12.

2. Standards & Specifications

Hastelloy C22 nuts comply with global standards for critical applications13:

- ASTM: B575 (sheet/plate), B619/B626 (welded pipes).

- ASME: SB-575 (pressure vessel components).

- EN: 2.4602 (Europe).

- Other: NACE MR0175 for sour gas environments.

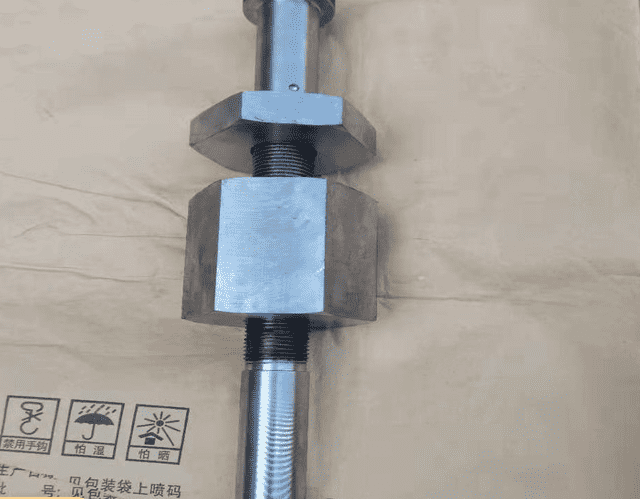

3. Types of Nuts Produced with Hastelloy C22

This alloy is ideal for manufacturing corrosion-resistant nuts, including:

- Hex Nuts (ASME B18.2.2)

- Flange Nuts (ASTM A194)

- Lock Nuts (DIN 985/982)

- Heavy Hex Nuts (ASME B18.2.6)23.

4. Application Fields

Hastelloy C22 nuts are widely used in industries demanding extreme durability:

- Chemical Processing: Reactors, heat exchangers, and sulfuric acid tanks12.

- Oil & Gas: Subsea pipelines, sour gas wells, and refinery equipment34.

- Marine Engineering: Desalination plants, seawater cooling systems12.

- Pharmaceuticals: High-purity processing equipment23.

5. Google AdWords Keywords

Optimize SEO with these keywords:

- Primary:

Hastelloy C22 Nuts, UNS N06022 Fasteners, EN 2.4602 Nuts, High-Corrosion-Resistant Alloy Nuts. - Long-Tail:

Hastelloy C22 Hex Nuts for Chemical Plants, C22 Alloy Lock Nuts Supplier, High-Temperature C22 Nuts for Oil & Gas. - Regional:

Hastelloy C22 Nuts USA, EN 2.4602 Nuts Europe, UNS N06022 Nuts Asia.

6. Technical Data Table

| Property | Value | Source |

| Tensile Strength | 690–760 MPa | 25 |

| Yield Strength | 310–350 MPa | 25 |

| Operating Temperature | Up to 600°C (1112°F) | 56 |

| Corrosion Resistance | Excellent (pH 1–12, Cl⁻/H₂S) | 14 |

Why Choose Hastelloy C22 Nuts?

Hastelloy C22 outperforms standard stainless steel and duplex alloys in aggressive environments. Its unique composition ensures longevity in applications involving sulfuric acid, chlorides, and hydrogen sulfide13.

- Hastelloy C22 Bolts” or “Learn about ASTM B575 Standards.”

- Hastelloy-C22-Nuts-Chemical-Plant.jpg – “Corrosion-resistant C22 nuts in sulfuric acid reactors.”

Meta Description:

“Discover Hastelloy C22 nuts (UNS N06022/EN 2.4602) – ideal for chemical, oil & gas, and marine industries. Superior corrosion resistance, high-temperature stability, and compliance with ASTM/EN standards. Request a quote now!”