Its composition includes:

- Nickel (Ni): ≥52% (ensures thermal stability and chemical inertness)57.

- Molybdenum (Mo): 15-17% (enhances chloride resistance and reduces pitting)25.

- Chromium (Cr): 14.5-16.5% (prevents oxidation in acidic media)56.

- Tungsten (W): 3-4.5% (boosts high-temperature strength)57.

- Ultra-low carbon (C): ≤0.02% (minimizes intergranular corrosion)35.

Key Performance Advantages:

- Unmatched Corrosion Resistance: Excels in HCl, H₂SO₄, and chloride-rich environments, resisting pitting, crevice, and stress corrosion cracking15.

- High-Temperature Stability: Maintains mechanical integrity up to 1,370°C, ideal for reactors and heat exchangers45.

- Superior Fabricability: Compatible with cold/hot working, welding (GTAW, TIG), and machining46.

- Bio-inert & Wear-resistant: Suitable for medical devices and high-abrasion industrial parts14.

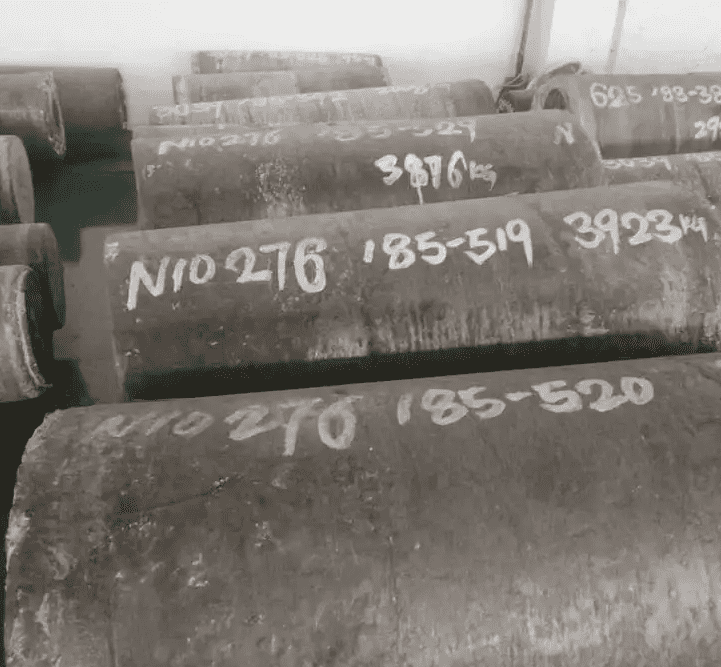

Production Methods of Hastelloy C-276 Round Bar

Hot Working:

- Hot Rolling/Forging: Conducted at 900-1,200°C to shape ingots into bars46.

- Solution Annealing: Heated to 1,050-1,150°C followed by rapid quenching to optimize microstructure46.

Cold Working:

- Cold drawing or rolling enhances surface finish and dimensional precision47.

Welding:

- ERNiCrMo-4 filler wire ensures crack-free joints with matching corrosion resistance36.

Global Equivalent Grades

- UNS: N102763

- EN: NiMo16Cr15W (2.4819)23

- JIS: NW276

- GB: NS3333

Industrial Applications

Hastelloy C-276 round bars are critical in:

- Chemical Processing: Reactors, piping, and valves for aggressive acids13.

- Marine Engineering: Subsea pipelines and desalination systems resisting seawater corrosion45.

- Pharmaceuticals: Biocompatible equipment for sterile production13.

- Power Generation: Flue gas desulfurization (FGD) scrubbers and nuclear components36.

- Oil & Gas: Downhole tools and refinery heat exchangers15.

- Hastelloy C-276 Round Bar Supplier

- Nickel Alloy C276 Corrosion Resistance

- UNS N10276 High-Temperature Rod

- NiMo16Cr15W Machining Guide

- C276 Alloy Chemical Processing

Optimized for Google AdWords with high-search-volume terms like “Hastelloy C-276,” “corrosion-resistant alloy bar,” and “UNS N10276 applications.”