Corrosion Resistance

- Exceptional resistance to wet chlorine, oxidizing chlorides, sulfuric acid, and hydrochloric acid at low-to-moderate temperatures 12.

- Resists pitting, crevice corrosion, and stress corrosion cracking (SCC) in chloride-rich environments 12.

Mechanical Properties

- Tensile Strength: ≥690 MPa | Yield Strength: ≥283 MPa | Elongation: ≥40% 12.

- Density: 8.89 g/cm³ | Hardness: ≤100 HRB (annealed condition) 13.

High-Temperature Performance

- Maintains mechanical stability and corrosion resistance at temperatures up to 1,090°C (2,000°F) 23.

3. Standards and Specifications

C276 nuts comply with:

- ASTM B574/B575: Standard for nickel-molybdenum-chromium alloy bars and forgings 24.

- ASME SB574/SB575: Equivalent specifications for pressure vessel components 23.

- DIN 934/936: Metric hex nuts and flange nuts 4.

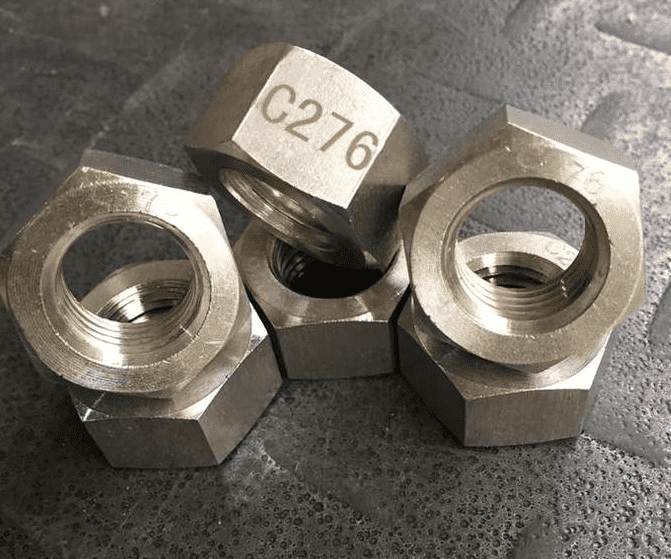

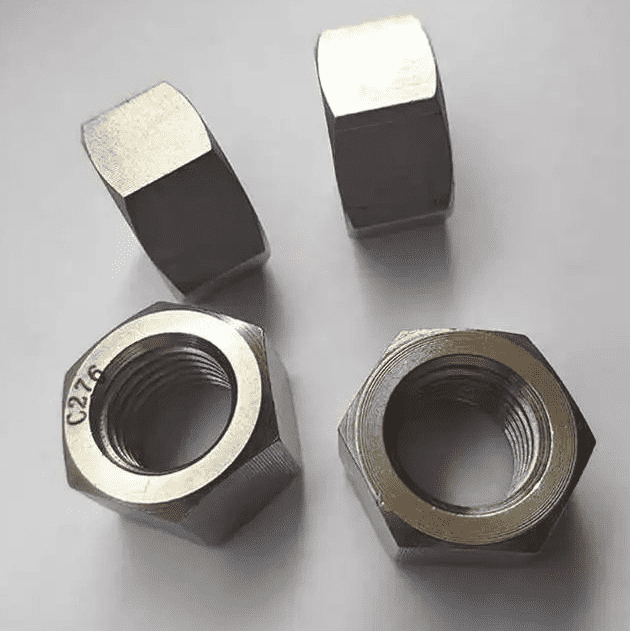

4. Types of Nuts Produced with C276

- Hex Nuts (ASTM A194 Gr. C276)

- Lock Nuts (e.g., Nylock, all-metal prevailing torque)

- Flange Nuts (SAE J995 compliant)

- Cap Nuts and Wing Nuts for specialized equipment 24.

5. Key Applications

Chemical & Petrochemical

- Reactors, heat exchangers, and piping systems handling sulfuric acid, hydrochloric acid, and chlorine 12.

Marine & Offshore

- Subsea fasteners, seawater pumps, and desalination plants 24.

Power Generation

- Flue gas desulfurization (FGD) systems and gas turbine components 23.

Pharmaceutical

- Sterile equipment and reactors requiring non-reactive materials 16.

- C276 Nuts

- Hastelloy C-276 Fasteners

- UNS N10276 Nuts

- High-Temperature C276 Nuts

- “Corrosion-Resistant C276 Hex Nuts for Chemical Plants”

- “Hastelloy C-276 Lock Nuts for Marine Applications”

- “ASTM B574 C276 Flange Nuts”

Suggested Tables

Table 1: Chemical Composition of Hastelloy C-276 (wt%)

| C ≤0.01 | Cr 14.5-16.5 | Mo 15-17 | Fe 4-7 | Ni ≥57 | W 3-4.5 | Co ≤2.5 | 37

Table 2: Mechanical Properties

| Tensile Strength | Yield Strength | Elongation | Hardness | |

| ≥690 MPa | ≥283 MPa | ≥40% | ≤100 HRB | 12 |

Conclusion

Hastelloy C-276 nuts are indispensable in industries demanding extreme corrosion resistance and thermal stability. Their compliance with ASTM/ASME standards and superior alloy composition (nickel-molybdenum-chromium) make them ideal for harsh chemical, marine, and high-temperature environments.

Keywords: C276 nuts, Hastelloy C-276 fasteners, UNS N10276, chemical processing nuts, marine-grade alloy nuts.

Include internal links to related products (e.g., “C276 bolts” or “Hastelloy C-276 washers”) and optimize meta descriptions with target keywords. Add alt-text for tables and images (e.g., “C276 hex nut corrosion resistance diagram”).