hemical composition: Its main chemical components include nickel (Ni) ≥ 65%, chromium (Cr) 1.00%-3.00%, molybdenum (Mo) 27.00%-32.00%, iron (Fe) 1.00%-3.00%, tungsten (W) ≤ 3.00%, carbon (C) ≤ 0.01%, silicon (Si) ≤ 0.10%, cobalt (Co) ≤ 3.00%, manganese (Mn) ≤ 3.00%, vanadium (V) ≤ 0.20%, phosphorus (P) ≤ 0.03%, sulfur (S) ≤ 0.01%, titanium (Ti) ≤ 0.20%, copper (Cu) ≤ 0.20%, aluminum (Al) ≤ 0.50%, zirconium (Zr) ≤ 0.10%, niobium / columbium (Nb/Cb) ≤ 0.20%, tantalum (Ta) ≤ 0.20%, and Ni + Mo content is 94.00%-98.00%

Metallurgical structure: Hastelloy B-3 has a face-centered cubic lattice structure. The iron and chromium content in the alloy is controlled at a low value, which prevents the precipitation of Ni4Mo phase between 700-800℃, thereby reducing the risk of processing embrittlement.

Main characteristics of Hastelloy B-3

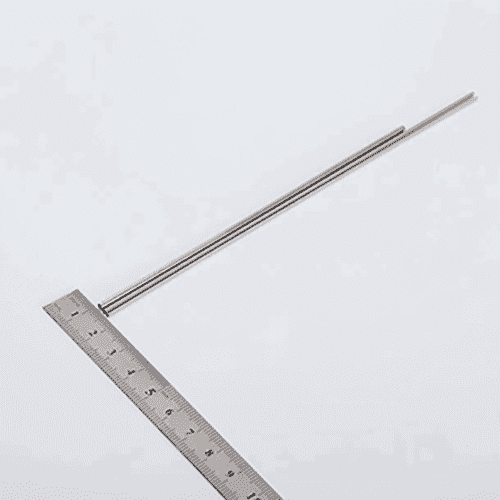

Mechanical properties: In the solid solution state, as the heating temperature increases, the tensile strength, yield strength and elastic modulus of Hastelloy B-3 plates will decrease, while the elongation, thermal expansion coefficient, thermal conductivity and specific heat will increase slightly; as the cold deformation rate increases, its hardness, tensile strength and yield strength increase, and the elongation decreases. Its tensile strength can reach more than 650MPa, elongation exceeds 45%, yield strength is more than 315MPa, hardness ranges between HB100-235, and density is about 9.22g/cm³.

Corrosion resistance:

It has excellent corrosion resistance to hydrochloric acid at any temperature and concentration, and also has good corrosion resistance to sulfuric acid, acetic acid, formic acid, phosphoric acid and other non-oxidizing media.

It has high resistance to pitting, stress corrosion, knife edge corrosion and corrosion of the heat affected zone of welding.

Processing performance:

The high elongation creates favorable conditions for cold forming, but it is harder than austenitic stainless steel, and has a more obvious tendency to work hardening. It requires greater pressure or step-by-step forming during cold forming.

When the cold forming deformation rate is less than 10%, it will not affect the corrosion resistance of the workpiece, but during welding, residual stress may cause thermal cracks in the weld. For workpieces that need welding processing later, residual stress should be eliminated as much as possible.

Cold forming with severe deformation will increase the yield strength ratio of the material and increase the sensitivity to stress corrosion and cracks. Intermediate and final heat treatment processes are often used.

It is very sensitive to oxidizing media and sulfur, phosphorus, lead and other low-melting-point metals at high temperatures. In the range of 600-800℃, a long heating time will produce a brittle phase, resulting in a decrease in elongation. In this temperature range, when external force or deformation is restricted, thermal cracks are prone to occur. The temperature must be controlled above 900℃ during hot forming.