Material Properties

Chemical Composition (wt%)

| Ni ≥65 | Mo 26-30 | Fe ≤2.0 | Cr ≤1.0 | C ≤0.02 | Mn ≤1.0 | Si ≤0.10 | 12.

Mechanical Properties

- Tensile Strength: ≥760 MPa | Yield Strength: ≥350 MPa | Elongation: ≥40% 12.

- Hardness: ≤220 HB (Brinell) | Density: 9.24 g/cm³ 12.

Corrosion Resistance

- Exceptional resistance to hydrochloric acid, sulfuric acid, and phosphoric acid at elevated temperatures 12.

- Superior performance in reducing media and high-stress environments 1.

3. Standards and Specifications

Hastelloy B2 nuts comply with:

- ASTM B574/B575: Standard for nickel-molybdenum alloy bars and forgings 12.

- ASME SB574/SB575: Equivalent specifications for pressure vessel components 1.

- DIN 934/936: Metric hex nuts and flange nuts 2.

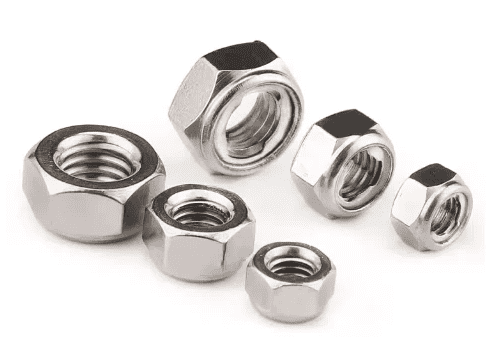

4. Types of Nuts Produced with Hastelloy B2

- Hex Nuts (ASTM A194 Grade B2)

- Flange Nuts (SAE J995 compliant)

- Lock Nuts (e.g., all-metal prevailing torque)

- Cap Nuts for high-corrosion environments 12.

5. Key Applications

Chemical & Petrochemical

- Reactors, heat exchangers, and piping systems handling hydrochloric acid and sulfuric acid 12.

Pharmaceutical

- Acid-resistant equipment and reactors for aggressive chemical synthesis 1.

Marine & Offshore

- Subsea components exposed to seawater and chloride-rich environments 2.

Power Generation

- Flue gas desulfurization (FGD) systems and scrubbers 1.

- Hastelloy B2 Nuts

- UNS N10665 Fasteners

- High-Corrosion Resistance Nuts

- ASTM B574 B2 Nuts

Long-Tail Keywords:

- “B2 Alloy Hex Nuts for Hydrochloric Acid Systems”

- “Marine-Grade Hastelloy B2 Flange Nuts”

- “High-Temperature B2 Lock Nuts”

Suggested Tables

Table 1: Chemical Composition of Hastelloy B2

| Element | Ni | Mo | Fe | Cr | C | Mn | Si | |

| wt% | ≥65 | 26-30 | ≤2.0 | ≤1.0 | ≤0.02 | ≤1.0 | ≤0.10 | 12. |

Table 2: Mechanical Properties

| Tensile Strength | Yield Strength | Elongation | Hardness | |

| ≥760 MPa | ≥350 MPa | ≥40% | ≤220 HB | 12. |

Conclusion

Hastelloy B2 nuts are indispensable in industries requiring extreme resistance to reducing acids and high-temperature corrosion. Their compliance with ASTM and ASME standards ensures reliability in critical applications such as chemical processing, marine engineering, and power generation.

Hastelloy B2 nuts, UNS N10665 fasteners, hydrochloric acid-resistant nuts, ASTM B574 B2.

“Hastelloy B2 nuts for hydrochloric acid systems.” Use internal links to related products (e.g., “Hastelloy B2 bolts” or “nickel-molybdenum alloy washers”) and add alt-text for tables (e.g., “B2 nut corrosion resistance comparison”).