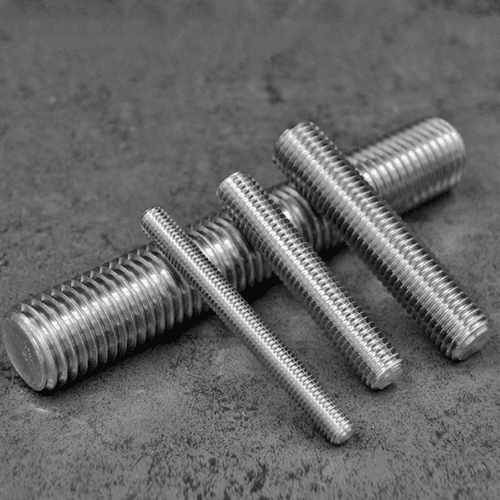

Studs have threads at both ends, and there are external thread studs and internal thread studs. Full-thread studs are studs without heads, and their entire body is threaded.

| All Material for full thread studs & full thread rods | ||||

| Hastelloy C276 | Duplex 2205 | A193 B8 | SS304 | Inconel600 |

| Hastelloy C22 | Duplex S31803 | B193 B8M | SS316 | Inconel601 |

| Hastelloy C4 | Super duplex S32750 | Alloy59 | SS316L | Incoloy718 |

| Monel400 | Super duplex 2507 | Alloy20 | Stainless steel 18-8 | Incoloy800H |

| Monelk500 | 904L | 309S | SS321 | Incoloy800 |

| Nimonic 80A | Alloy 926 -UNS N08926 | 310S | 317L | Incoloy825 |

- Differences between studs and full-thread studs

- Different end structures

Studs,for exemple duplex s31803 stud have threads and head structures at both ends, which are suitable for occasions where two or more objects need to be connected. Full-thread studs have no heads and are mainly used in occasions that require encryption and fixation.

- Different application scenarios

Studs are usually used in the connection of some tightly connected mechanical parts. For example, the base of the machine is connected and the installation of mechanical parts, as well as some polishing uses. Full-thread studs can be used to fix and strengthen workpieces, and can also be used to connect two objects, especially in occasions that need to be tightly fixed.

- Different installation methods

The installation methods of studs and full-thread studs are also different. Studs need to be tightened to a specific torque during installation to ensure the stability of the connection. The full-thread stud needs to be screwed directly into the workpiece, and its screw-in depth should be 1.5 times the thread diameter.

- How to choose when using

When you need to connect two objects, give priority to studs, because its design makes the connection tighter and more stable. The full-thread stud is suitable for tight fixing occasions that do not require a head design.

- Summary

Through the introduction of this article, we can clearly understand the difference between studs and full-thread studs, and how to choose studs that suit our needs. Correct selection according to needs during use can better meet the requirements of mechanical connection.