Its exceptional properties stem from precise chemical composition:

- Chemical Composition: 22% Cr, 5% Ni, 3% Mo, and 0.14–0.20% N 13.

- Key Performance:

- High Strength: Tensile strength up to 620 MPa and yield strength of 450 MPa, surpassing 304/316 stainless steels 57.

- Corrosion Resistance: Superior resistance to chloride-induced pitting, stress corrosion cracking (SCC), and acidic environments 14.

- Thermal Stability: Maintains performance at both high and low temperatures 45.

2. Standards & Specifications

Duplex 2205 nuts comply with globally recognized standards:

- ASTM: A240/A240M (plate/sheet), A276 (bar), A193/A194 (fasteners) 16.

- EN: 1.4462 (Europe) 23.

- Other: NAS 329J3L (Japan) 3.

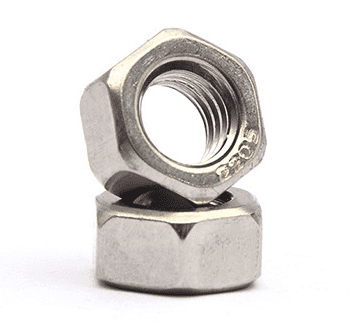

3. Types of Nuts Produced with Duplex 2205

This material is ideal for manufacturing high-performance nuts, including:

- Hex Nuts (ASTM A194)

- Flange Nuts (ASME B18.2.2)

- Lock Nuts (DIN 985/982)

- Heavy Hex Nuts (ASME B18.2.6)

4. Application Fields

Duplex 2205 nuts excel in demanding environments:

- Oil & Gas: Subsea pipelines, pressure vessels, and offshore platforms 67.

- Chemical Processing: Reactors, tanks, and acid-resistant equipment 46.

- Marine Engineering: Desalination plants, shipbuilding, and coastal infrastructure 13.

- Food & Pharma: Hygienic equipment requiring corrosion resistance 6.

- Primary:

Duplex 2205 Stainless Steel Nuts, UNS S32205 Nuts, ASTM A240 Nuts, EN 1.4462 Fasteners. - Long-Tail:

High Strength Corrosion Resistant Nuts, Duplex 2205 Nuts for Marine Applications, 2205 Stainless Steel Hex Nuts Supplier. - Regional:

Duplex 2205 Nuts USA, EN 1.4462 Nuts Europe, S31803 Nuts Asia.

Why Choose Duplex 2205 Nuts?

Duplex 2205 combines cost efficiency with extreme durability, reducing maintenance costs in corrosive environments. Its dual-phase structure ensures longevity in applications where traditional stainless steels fail 34.

Internal Linking Tip:

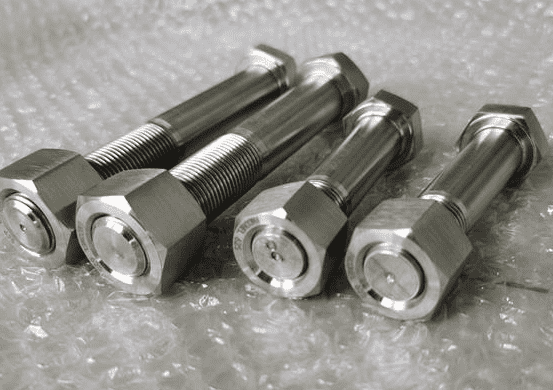

- Link to related products (e.g., “Explore Duplex 2205 Bolts for full fastener solutions”).

I

Duplex-2205-Stainless-Steel-Nuts-Marine-Environment.jpg – “Corrosion-resistant Duplex 2205 nuts in seawater applications”.

Meta Description:

“Discover Duplex 2205 stainless steel nuts (UNS S32205/S31803) – high strength, corrosion-resistant fasteners for oil, gas, marine, and chemical industries. Compliant with ASTM/EN standards. Get quotes today!”