Its unique composition includes:

- Nickel (Ni): ≈30% (enhances corrosion resistance and stability)13

- Chromium (Cr): ≈28% (provides high-temperature oxidation resistance and improves general corrosion resistance)13

- Molybdenum (Mo): ≈6% (increases resistance to pitting and crevice corrosion)13

- Iron (Fe): Balance (contributes to mechanical strength and cost-effectiveness)1

Similar Grades:

- UNS N08031 (USA), 1.4562 (DIN/Germany), Incoloy 31 (trade name)134

Outstanding Performance Characteristics

Superior Corrosion Resistance:

- Resistant to sulfuric acid, phosphoric acid, and chloride-induced stress corrosion cracking (SCC) up to high temperatures235.

- Excellent performance in seawater, brine, and other chloride-containing environments24.

High-Temperature Strength:

- Maintains mechanical properties at temperatures up to 1000°C (1832°F), with good creep resistance23.

- Tensile strength: typically ≥620 MPa; Yield strength: ≥275 MPa; Elongation: ≥35%13.

Excellent Weldability:

- Suitable for all common welding processes, including TIG, MIG, and submerged arc welding34.

- Low risk of sensitization and intergranular corrosion in the heat-affected zone (HAZ)23.

Production Techniques

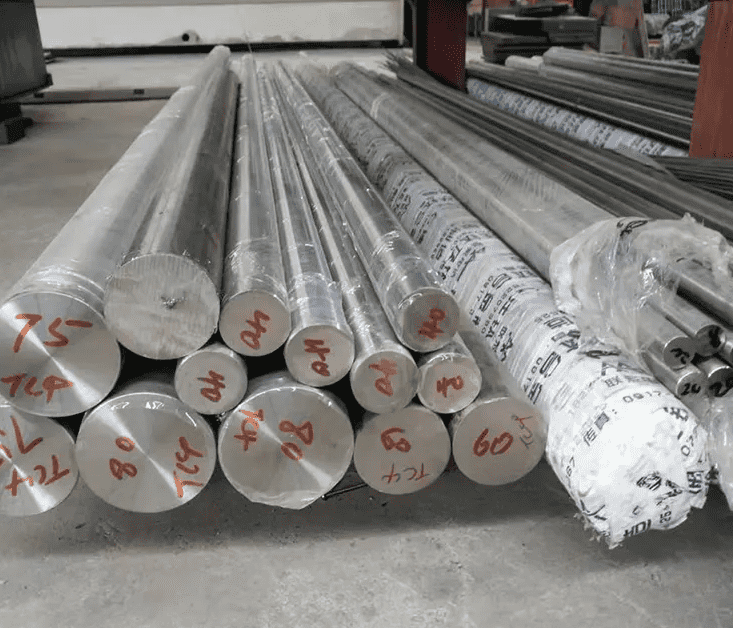

Alloy31 round bars are meticulously produced through:

Melting & Casting:

- Vacuum induction melting (VIM) or electric arc melting (EAF) to ensure high purity and uniform composition13.

- Continuous casting or ingot casting followed by hot rolling to form billets14.

Thermal Processing:

- Hot working at temperatures between 1000°C and 1250°C (1832°F to 2282°F) for shaping and sizing13.

- Solution annealing at 1010°C to 1150°C (1850°F to 2093°F) followed by rapid cooling to optimize microstructure14.

Finishing:

- Cold drawing, grinding, or polishing to achieve precise dimensions and surface finishes134.

Wide Range of Applications

Alloy31 round bars find their place in:

- Chemical Processing: Reactors, heat exchangers, and storage tanks for sulfuric acid, phosphoric acid, and other corrosive chemicals235.

- Oil & Gas: Downhole equipment, pipelines, and valves in sour gas and high-temperature oilfield services35.

- Marine Engineering: Offshore platforms, seawater desalination plants, and shipbuilding components exposed to marine environments24.

- Power Generation: Flue gas desulfurization systems, nuclear reactor components, and thermal power plant equipment345.

- Alloy31 Round Bar

- UNS N08031 Nickel-Chromium Alloy

- 4562 Corrosion-Resistant Rod

- Incoloy 31 Supplier

- High-Temperature Alloy31 Stock

Certified suppliers offer Alloy31 round bars in diameters ranging from 6mm to 300mm, complying with ASTM B409, EN 10088-1, and other international standards134.

Alloy31 round bar, UNS N08031 alloy, 1.4562 supplier, corrosion-resistant nickel-chromium alloy.