Material Composition & Similar Grades

Key elements include:

Nickel (Ni): 30–34% (ensures austenitic structure and corrosion resistance)4.

- Chromium (Cr): 26–28% (boosts oxidation and chloride resistance)45.

- Molybdenum (Mo): 3–4% (prevents pitting and crevice corrosion)34.

- Copper (Cu): ~1% (improves sulfuric acid resistance)35.

Similar Grades:

- UNS N08028 (USA), 1.4563 (DIN/Germany), Sanicro 28 (commercial name)34.

Key Performance Features

Exceptional Corrosion Resistance:

- Resists sulfuric acid (up to 85% concentration), phosphoric acid, and chloride-induced stress corrosion cracking (SCC)23.

- Maintains integrity in seawater, acidic/alkaline media, and high-temperature steam (up to 585°C)23.

High-Temperature Mechanical Stability:

- Tensile strength: ≥800 MPa; Yield strength: ≥300 MPa; Elongation: ≥35%13.

- Retains strength and ductility at 600–650°C, ideal for thermal cycling24.

Fabrication Flexibility:

- Hot working: Forged or rolled at 900–1200°C for shaping14.

- Cold working: Cold rolling/drawing for precision dimensions and enhanced strength13.

- Heat treatment: Solution annealing (1000–1200°C) + rapid cooling to optimize microstructure14.

Production Methods

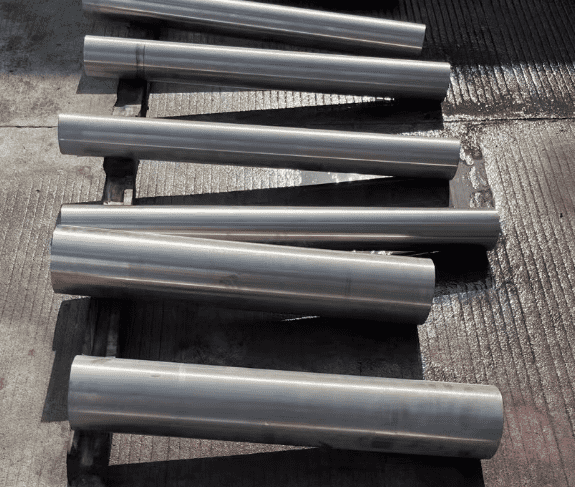

Alloy28 round bars are manufactured through:

- Vacuum Melting: Ensures low carbon content (≤0.009%) to avoid carbide precipitation45.

- Forming Processes:

- Hot extrusion or rolling to form billets14.

- Cold drawing for tight tolerances and smooth surfaces13.

- Surface Finishing: Grinding or polishing to achieve ASTM/EN-specified surface quality35.

Applications in Critical Industries

Alloy28 round bars excel in:

- Chemical Processing: Reactors, heat exchangers, and sulfuric acid storage tanks23.

- Oil & Gas: Subsea pipelines, valves, and sour gas well components35.

- Marine Engineering: Offshore platforms, desalination systems, and seawater pumps35.

- Power Generation: Nuclear reactor components and flue gas scrubbers34.

- Medical Devices: Implants and surgical tools requiring biocompatibility3.

SEO-Optimized Keywords

Boost visibility with Google AdWords-ready terms:

- Alloy28 Round Bar

- UNS N08028 Nickel-Chromium Alloy

- Sanicro 28 Corrosion-Resistant Rod

- High-Temperature Alloy 1.4563 Supplier

- Industrial Alloy28 Stock

Certified suppliers offer Alloy28 round bars in diameters 10–500mm, compliant with ASTM B668, EN 10088-1, and NACE MR0175 standards34.