- Equivalent Grades:

- UNS: N08367

- EN/DIN: 4501

- China GB: 00Cr21Ni24Mo6N 12

- Material Composition:

| Element | Ni | Cr | Mo | N | Fe | |

| % Range | 23.5–25.5% | 20.0–22.0% | 6.0–7.0% | 0.18–0.25% | Bal. | 14 |

Material Properties

- Corrosion Resistance:

- Exceptional resistance to chlorides, sulfuric acid, and seawater, outperforming 300-series stainless steels 24.

- Superior resistance to pitting, crevice corrosion, and stress corrosion cracking (SCC) in harsh environments like marine and chemical processing 13.

- Mechanical Strength:

- Tensile strength: ≥650 MPa

- Yield strength: ≥310 MPa

- Elongation: ≥30% 48.

- Physical Properties:

- Density: 24 g/cm³

- Melting range: 1320–1400°C

- Thermal expansion coefficient: 2 × 10⁻⁶/°C (100–500°C) 4.

Standards & Certifications

- ASTM: B688 (plate, sheet, strip)

- DIN: 1.4501

- ISO: 4032 (hex nuts), 7040 (flange nuts)

- ANSI/ASME: B18.2.2 (metric nuts) 56.

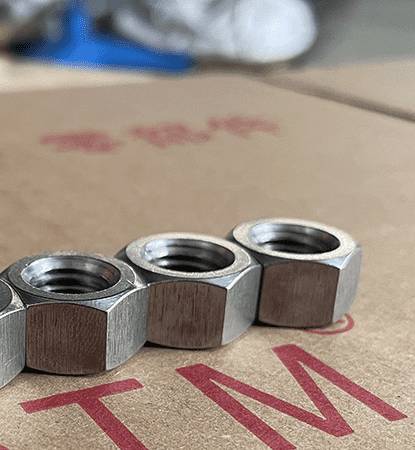

Types of Nuts Produced with AL6XN

- Hex nuts (DIN 934, ISO 4032)

- Flange nuts (ISO 7040)

- Lock nuts (DIN 985)

- Coupling nuts (ANSI B18.2.2)

- Customizable threads: UNC, UNF, metric 56.

Applications Across Industries

- Marine & Offshore:

- Fasteners for seawater-cooled condensers, offshore platforms, and shipbuilding 28.

- Chemical & Petrochemical:

- Reactors, pipelines, and valves handling chlorinated solvents or sulfuric acid 14.

- Energy & Power Generation:

- Flue gas desulfurization (FGD) systems, nuclear reactor coolant pipelines 48.

- Pharmaceutical & Food Processing:

- Hygienic fasteners resistant to sterilization chemicals and acidic cleaning agents 48.

AL6XN nuts

- UNS N08367 fasteners

- Super austenitic stainless steel nuts

- DIN 1.4501 nuts

- High-molybdenum corrosion-resistant nuts

- Marine-grade stainless steel nuts

- ASTM B688 hex nuts

- Chemical industry fasteners

- AL6XN Nuts: Grades & Applications”).

- Learn about AL6XN tubing for chemical plants”).

- AL6XN Hex Nuts in Offshore Platform Assembly”.