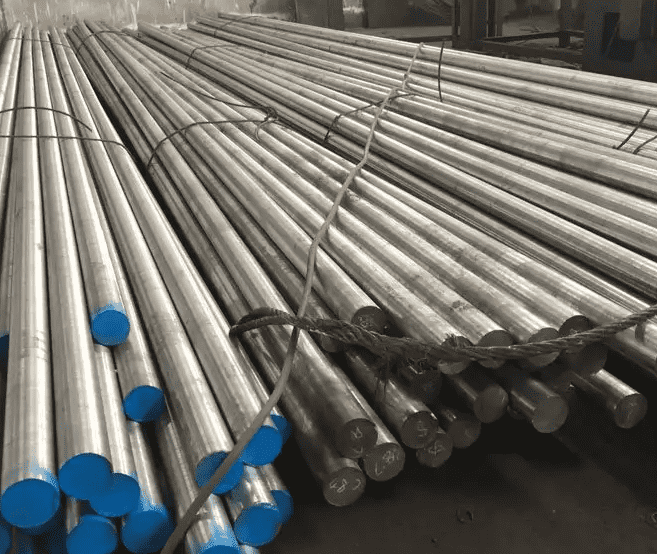

347 stainless steel round bar is an austenitic stainless steel stabilized with niobium (Nb), offering excellent corrosion resistance and high-temperature stability.

Round bar AISI 347 Chemical Composition

- Carbon (C): ≤0.08%

- Chromium (Cr): 17.0–19.0%

- Nickel (Ni): 9.0–13.0%

- Niobium (Nb): 0.40–1.00%

- Manganese (Mn): ≤2.0%

- Silicon (Si): ≤1.0%

- Iron (Fe): Balance 12.

Stainless steel AISI347 bar Physical & Mechanical Properties

- Density: 7.96 g/cm³

- Melting Range: 1398–1446°C

- Tensile Strength: 515–860 MPa

- Yield Strength: ≥205 MPa

- Elongation: ≥40%

- Hardness: ≤95 HRB 12.

Machining Methods

347 stainless steel round bars are widely used in high-temperature and corrosive environments. Key machining considerations include:

- Hot Working

Recommended forging/upsetting temperature: 2100°F (1150°C).

Maintain uniform heating to avoid cracking during hot forming 34.

- Cold Working

High work-hardening rate requires intermediate annealing for severe cold-forming operations (e.g., spinning, deep drawing) 14.

- Cutting & Turning

Use rigid tools and positive feeds to minimize work hardening.

Optimize cutting parameters:

Low-to-medium speeds with consistent feed rates.

Carbide tools (e.g., tungsten carbide) recommended for durability 45.

- Heat Treatment

- Solution Annealing: Heat to 1900–2150°F (1038–1177°C), followed by rapid cooling to retain corrosion resistance 2.

Performance Highlights

Corrosion Resistance:

- Superior resistance to intergranular corrosion, especially in welded or high-temperature environments (up to 800°C). Nb stabilizes the structure, preventing chromium carbide formation 12.

High-Temperature Stability:

- Maintains mechanical strength and oxidation resistance in applications like boilers, heat exchangers, and chemical processing equipment 26.

Mechanical Durability:

- High tensile strength and elongation ensure reliability under cyclic thermal and mechanical loads 12.

Applications

- Petrochemical heat exchangers

- High-temperature steam piping

- Aerospace components

- Heavy-duty exhaust systems 24.

For further technical details or custom processing guidance, contact our engineering team