Material Properties of 316L Nuts

316L is a low-carbon, molybdenum-enhanced austenitic stainless steel with superior performance in harsh environments:

Chemical Composition 13:

- Carbon (C): ≤0.03% (prevents carbide precipitation during welding).

- Chromium (Cr): 16–18% (enhances oxidation resistance).

- Nickel (Ni): 10–14% (improves ductility and corrosion resistance).

- Molybdenum (Mo): 2–3% (resists pitting/crevice corrosion in chlorides).

- Mechanical Properties 13:

- Tensile Strength: ≥520 MPa

- Yield Strength: ≥205 MPa

- Elongation: ≥40%

- Hardness: ≤217 HBW

- Corrosion Resistance 14:

- Excellent resistance to seawater, acids (sulfuric, phosphoric), and chloride-induced stress corrosion cracking (SCC).

- Performs well in temperatures up to 400°C 45.

Standards for 316L Nuts

316L nuts comply with stringent global certifications:

- ASTM: ASTM A240/A240M (plate/bar), ASTM A193 (high-temperature bolts/nuts) 15.

- ISO: ISO 3506-3 (corrosion-resistant fasteners) 35.

- EN/DIN: EN 1.4404 / DIN 1.4404 58.

- ASME: B16.5/B18.2.2 (flange/hex nut dimensions) 15.

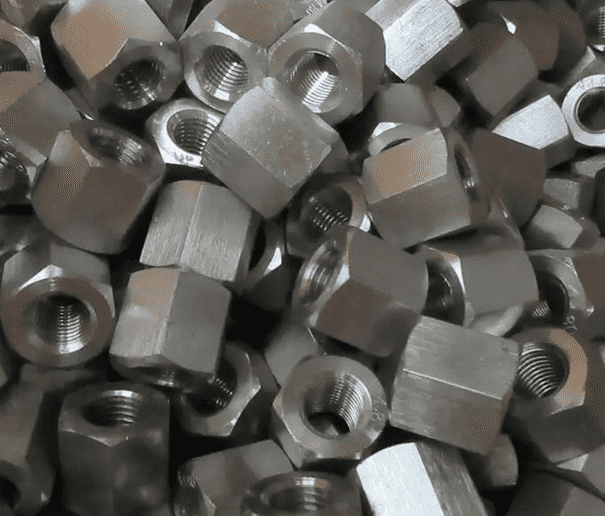

Types of Nuts Manufactured with 316L

316L’s weldability and strength make it ideal for producing:

- Hex Nuts: General-purpose ISO 4032-compliant nuts 15.

- Lock Nuts: Nylon-insert or all-metal designs for vibration resistance 26.

- Flange Nuts: Used in high-pressure pipelines and chemical reactors 67.

- Heavy Hex Nuts: Structural applications requiring higher load capacity 57.

Key Applications

316L nuts are critical in industries demanding corrosion resistance and durability:

- Marine Engineering: Offshore platforms, shipbuilding, and desalination systems 14.

- Chemical Processing: Reactors, heat exchangers, and acid storage tanks 14.

- Oil & Gas: Subsea equipment, pipelines, and sour gas handling 47.

- Medical & Food: Surgical instruments, pharmaceutical equipment, and food-grade machinery 15.

- 316L stainless steel nuts

- Marine-grade 316L hex nuts

- ASTM A240 316L fasteners

- Corrosion-resistant lock nuts

- DIN 1.4404 flange nuts

- High-temperature 316L nuts

- ISO 3506 compliant nuts

- 316L nuts for chemical industry

Suggested Visuals for Enhanced Engagement

- Corrosion Rate Comparison Chart: 316L vs. 304 stainless steel in seawater and sulfuric acid 14.

- Temperature vs. Strength Curve: Illustrate tensile strength retention from 20°C to 400°C 45.

- Application Distribution Chart: Highlight usage in marine (35%), chemical (30%), oil & gas (25%), and medical (10%) sectors 14.

Why Choose 316L Nuts?

316L’s low carbon content and molybdenum addition ensure superior weldability and resistance to localized corrosion, outperforming standard 304 stainless steel in aggressive environments 14. Compliance with ASTM, ISO, and DIN standards guarantees reliability across critical applications 35.

Conclusion

316L stainless steel nuts offer unmatched corrosion resistance, mechanical strength, and versatility for marine, chemical, and industrial applications. Optimize SEO with keywords like “marine-grade 316L nuts” or “ASTM A240 fasteners” to target engineers and procurement teams seeking durable, compliant solutions.

Note: For custom specifications, use terms like “DIN 1.4404 custom flange nuts” or “ISO 3506 316L lock nuts” to capture niche queries.