316 stainless steel is internationally recognized under multiple standards:

- ASTM/AISI: AISI 316 / ASTM A193 B8M 5

- ISO/EN: 1.4401 (316), 1.4404 (316L) 5

- JIS: SUS316 4

- DIN: 1.4571 (316Ti with titanium addition for enhanced corrosion resistance) 23

Material Performance Highlights:

- Corrosion Resistance:

- Superior resistance to chlorides, acids, and marine environments 24.

- Ideal for chemical processing and coastal applications 35.

- High-Temperature Stability:

- Maintains structural integrity up to 870°C (1600°F) 45.

- Mechanical Strength:

- Tensile strength: 515–690 MPa | Yield strength: 205–310 MPa 5.

- Machinability:

- Suitable for precision manufacturing of complex nut designs 48.

Standards for 316 Stainless Steel Nuts

316 nuts comply with global specifications:

- ASME/ANSI: Heavy Hex Nuts (e.g., ANSI B18.2.2) 1

- DIN: DIN 934 (Hex Nuts), DIN 316 (Butterfly Nuts) 67

- ISO: ISO 4032 (Hex Nuts) 7

- JIS: JIS B 1181 (Flange Nuts) 4

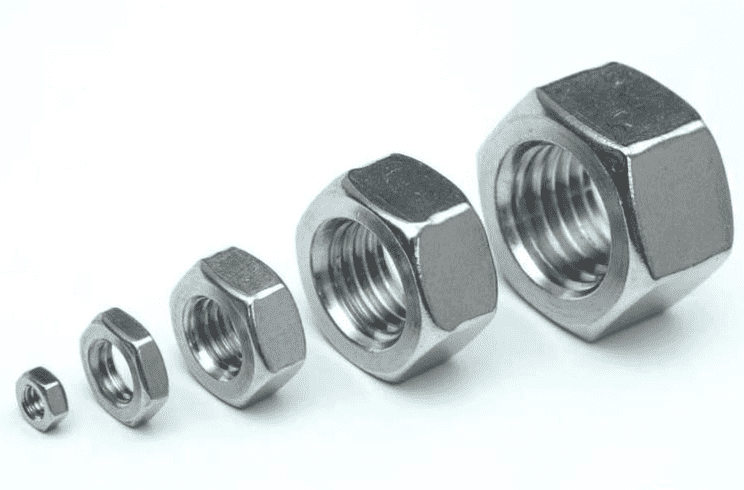

Types of Nuts Produced with 316 Stainless Steel

Manufacturers use 316 steel to produce:

- Heavy Hex Nuts: ANSI/ASME-compliant for industrial machinery 18.

- Lock Nuts: High-strength alloy variants (e.g., Spieth AL/IL series) for vibration resistance 7.

- Flange Nuts: Integrated washers for load distribution 4.

- Butterfly Nuts: DIN 316-standardized for easy manual adjustment 6.

- Cap Nuts: Aesthetic and protective designs for architectural use 8.

Applications of 316 Stainless Steel Nuts

- Marine & Offshore: Resists saltwater corrosion in shipbuilding and rigs 24.

- Chemical Processing: Tanks, reactors, and piping systems 25.

- Pharmaceutical & Food: Hygienic, non-reactive surfaces for equipment 4.

- Automotive & Aerospace: High-stress fasteners in engines and structural components 78.

- Renewable Energy: Solar panel mounts and wind turbine assemblies 5.

- Primary Keywords:

316 Stainless Steel Nuts, AISI 316 Hex Nuts, Marine Grade Stainless Nuts, DIN 316 Butterfly Nuts - Long-Tail Keywords:

High-temperature 316 nuts for chemical plants, SUS316Ti corrosion-resistant nuts, ANSI B18.2.2 heavy hex nuts supplier - Regional Keywords:

316 stainless steel nuts China manufacturer, DIN 934 nuts Europe distributor

Suggested Visual Content

- Comparison Table: 316 vs. 304 stainless steel properties.

- Infographic: Applications across industries (marine, chemical, automotive).

- Mechanical Properties Chart: Tensile strength vs. temperature.

Conclusion

316 stainless steel nuts offer unmatched versatility in harsh environments. By aligning with international standards (ASTM, DIN, JIS) and targeting niche applications, manufacturers can leverage keywords like SUS316Ti nuts or marine-grade hex nuts to enhance SEO performance. For quotes or custom specifications, include CTAs like “Contact 316 nuts suppliers today” to drive engagement.

Keywords: 316 stainless steel nuts, AISI 316 hex nuts, DIN 934 nuts, marine-grade nuts, SUS316Ti nuts, ANSI B18.2.2 nuts, high-temperature fasteners.