310S stainless steel is internationally recognized under multiple standards:

- UNS: S31008

- ASTM: 310S (S31000)

- JIS: SUS310S (SUH310)

- DIN: 1.4845

- EN: X15CrNiSi25-21 14

2. Material Properties of 310S

310S is an austenitic stainless steel with exceptional performance in extreme environments:

- Chemical Composition:

- Cr: 24-26%, Ni: 19-22%, C: ≤0.08% 13

- Mechanical Properties:

- Tensile Strength: ≥515 MPa

- Yield Strength: ≥205 MPa

- Elongation: ≥35% 24

- Key Advantages:

- High-Temperature Resistance: Up to 1150°C (continuous use) and 1200°C (peak) 28

- Oxidation & Corrosion Resistance: Ideal for acidic, alkaline, and marine environments 37

- Weldability & Formability: Suitable for complex machining and welding processes 35

3. Standards for 310S Nuts

310S nuts comply with global industrial standards:

- Material Standards:

- ASTM A240 (General Requirements) 4

- ASTM A276 (Bar & Wire Specifications) 2

- Mechanical Performance Standards:

- ASTM A354: Grade BC (High-Strength Applications) 5

- GB/T 3098.6: Grade A4-70/A4-80 (China) 5

- ASME B18.31.2: Dimensional tolerances for threaded fasteners 5

4. Types of Nuts Produced with 310S

310S is used to manufacture nuts for specialized environments:

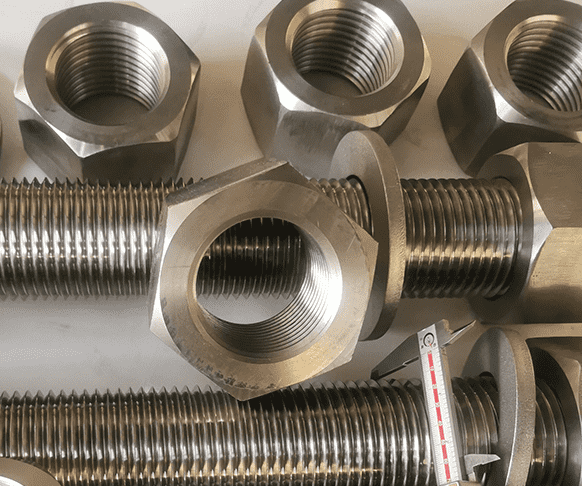

- Hex Nuts: High-strength fasteners for boilers and reactors 68

- Flange Nuts: Sealing solutions for pipelines and valves 5

- Lock Nuts: Vibration-resistant designs for aerospace components 7

- Heavy Hex Nuts: For structural connections in power plants 8

5. Applications of 310S Nuts

Industries:

- Oil & Gas: Reactors, pipelines, and heat exchangers 78

- Power Generation: Nuclear reactor components, turbine systems 8

- Chemical Processing: Acid-resistant tanks and pumps 38

- Automotive: Exhaust systems and catalytic converters 7

- High-Temperature Furnaces: Oven parts, kiln fixtures 28

Incorporate these high-traffic keywords:

- Primary: 310S Stainless Steel Nuts, High Temperature Nuts, ASTM A240 Nuts

- Secondary: Corrosion Resistant Hex Nuts, 310S Lock Nuts, UNS S31008 Fasteners

- Long-Tail: 310S Nuts for Chemical Plants, 310S Flange Nuts Price, 310S vs 316L Nuts Comparison

Visual Content (Example Table)

| Property | 310S | 304 | 316L |

| Max Temperature (°C) | 1200 | 870 | 800 |

| Corrosion Resistance | Excellent | Good | Superior |

| Tensile Strength (MPa) | 515 | 505 | 485 |

Image Suggestion:

- Alt Text: “310S Hex Nuts in High-Temperature Applications”

Internal & External Linking Strategy

- Internal Links:

- “Explore our 310S Flange Nuts for industrial pipelines.”

- “Compare 310S vs 316L nuts for your project.”

- ASTM Standards: ASTM A240

- Material Certifications: UNS S31008 Datasheet

310S stainless steel nuts deliver unmatched durability in extreme conditions. Optimize procurement by aligning with ASTM, EN, or JIS standards 24. For bulk orders or custom specifications, request a quote today!