Its key composition includes:

- Chromium (Cr): 15.0–17.5%

- Nickel (Ni): 3.0–5.0%

- Copper (Cu): 3.0–5.0%

- Niobium (Nb): 0.15–0.45%

- Carbon (C): ≤0.07%

- Other Elements: Manganese (Mn) ≤1.0%, Silicon (Si) ≤1.0%, Phosphorus (P) ≤0.04%, Sulfur (S) ≤0.03%23.

Physical & Mechanical Properties:

- Density: 7.75 g/cm³

- Tensile Strength: Up to 1,310 MPa (H900 condition)

- Yield Strength: Up to 1,172 MPa (H900 condition)

- Elongation: ≥10% (H900 condition)

- Hardness: HRC 40–45 (H900 condition)34.

Product Performance Highlights

High Strength & Durability:

- Achieves superior tensile and yield strength through precipitation hardening, making it ideal for high-stress applications such as aerospace components and industrial machinery14.

- Maintains toughness even at elevated temperatures (up to 316°C)4.

Excellent Corrosion Resistance:

- Resists atmospheric corrosion, mild acids, and chloride environments, outperforming 400-series martensitic stainless steels45.

- Comparable corrosion resistance to Type 304 stainless steel in many environments4.

Versatile Fabrication:

- Easily machined, welded, and cold-worked using standard methods. Post-weld heat treatment ensures uniform mechanical properties35.

Magnetic Properties:

- Exhibits magnetic behavior in hardened conditions, suitable for specialized industrial applications6.

Production Methods

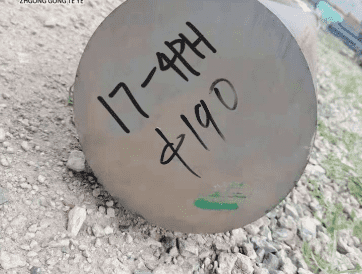

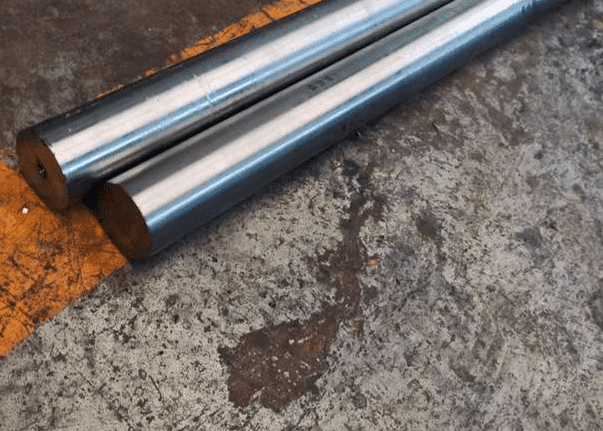

17-4PH round bars are manufactured through a precise process:

- Melting & Casting:

- Raw materials are melted in electric arc furnaces (EAF) and refined to achieve precise chemical composition34.

- Hot Rolling:

- Cast ingots are heated to 1,150–1,200°C and hot-rolled into round bars to refine grain structure36.

- Heat Treatment:

- Solution Annealing: Heated to 1,038°C, held for 1 hour, then rapidly cooled to form a uniform microstructure36.

- Aging (Precipitation Hardening): Heated to 480–620°C for 4–8 hours to precipitate strengthening phases (e.g., copper-niobium compounds)36.

- Finishing:

- Bars are ground, polished, or coated to meet dimensional and surface-quality standards6.

Equivalent Grades & Standards

- UNS S17400

- ASTM A564, ASTM A693, AMS 5604

- DIN 1.4542, EN X5CrNiCuNb16-4

- JIS SUS630, GB 0Cr17Ni4Cu4Nb23.

Key Application Fields

17-4PH round bars are widely used in industries demanding high strength and reliability:

- Aerospace:

- Aircraft structural components, landing gear parts, and fasteners14.

- Medical Devices:

- Surgical instruments, orthopedic implants, and dental tools due to biocompatibility and strength13.

- Oil & Gas:

- Valve components, pump shafts, and downhole tools exposed to corrosive media45.

- Industrial Machinery:

- Gears, bearings, and high-stress mechanical parts requiring wear resistance6.

- Nuclear & Energy:

- Reactor components and turbine parts for high-temperature stability34.

- 17-4PH Round Bar Supplier

- UNS S17400 High-Strength Stainless Steel

- Precipitation-Hardening 17-4PH Rod

- ASTM A564 17-4PH Round Bar

- Aerospace-Grade 17-4PH Applications

- Medical-Grade 17-4PH Machining

- Corrosion-Resistant 17-4PH Alloy

17-4PH round bars deliver unmatched strength and corrosion resistance for critical applications. For custom specifications or bulk orders, partner with a certified supplier specializing in high-performance stainless steel alloys.