Chemical Composition

| Element | Cr | Ni | Cu | Mn | Nb+Ta | Fe | |

| % Range | 15–17.5 | 3–5 | 3–5 | ≤1 | 0.15–0.45 | Bal. | 35 |

Mechanical Properties

- Tensile Strength: ≥1310 MPa (H900 temper)

- Yield Strength: ≥1172 MPa (H900 temper)

- Hardness: 388–444 HBW (H900 temper)

- Elongation: ≥10% 35

Physical Properties

- Density: 7.75 g/cm³

- Melting Range: 1400–1440°C 13

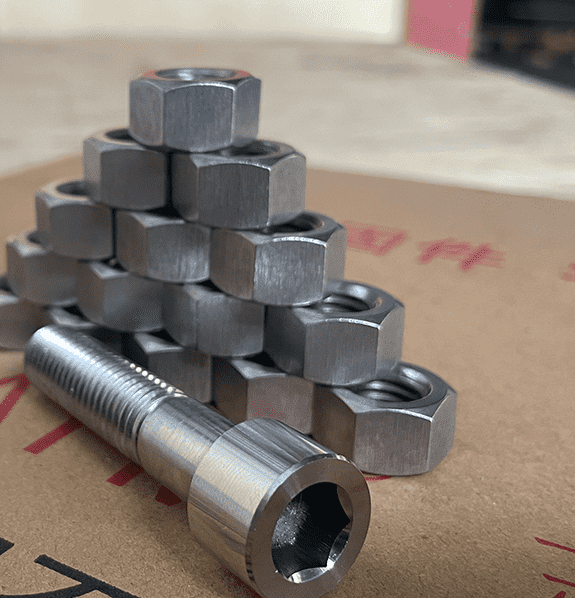

Types of Nuts Produced with 17-4PH

- Hex Nuts (ISO 4032 / DIN 934)

- Flange Nuts (ISO 7040)

- Lock Nuts (DIN 985)

- High-Strength Coupling Nuts (ANSI B18.2.2)

- Customizable threads: UNC, UNF, Metric 15

Applications Across Industries

- Aerospace:

- Jet engine components, turbine blades, and structural fasteners requiring high strength-to-weight ratios 67.

- Marine & Offshore:

- Fasteners for seawater-resistant platforms, helicopter decks, and shipbuilding 78.

- Chemical & Energy:

- Valves, pump shafts, and nuclear waste containment barrels exposed to corrosive media 35.

- Medical & Food Processing:

- Surgical instruments and hygienic equipment needing sterilization compatibility 67.

- 17-4PH nuts

- UNS S17400 fasteners

- High-strength stainless steel nuts

- ASTM A564 hex nuts

- DIN 1.4542 fasteners

- Aerospace-grade nuts

- Corrosion-resistant coupling nuts

- Precipitation-hardening stainless steel nuts

Heat Treatment & Machining

- Solution Annealing: 1038°C ± 14°C followed by rapid cooling 36.

- Precipitation Hardening:

- H900: 480°C aging → peak hardness (HRC 35–44) 13.

- Weldability: Compatible with TIG/MIG; post-weld heat treatment recommended 56.

Why Choose 17-4PH Nuts?

- Cost Efficiency: Combines strength of high-grade alloys with lower material costs 5.

- Versatility: Adaptable to harsh environments (corrosion, high stress, extreme temps) 67.

- 17-4PH Nuts: Aerospace Applications”).

- Explore 17-4PH bolts for offshore rigs”).

- 17-4PH Hex Nuts in Jet Engine Assembly”.