The key elements in its composition include:

- Chromium (Cr): 20.0-22.0%

- Nickel (Ni): 23.0-25.0%

- Molybdenum (Mo): 6.0-7.0%

- Copper (Cu): 1.0-2.0%

- Nitrogen (N): 0.15-0.25%

- Low Carbon (C): ≤0.02%

- Additional Elements: Manganese (Mn) ≤1.0%, Silicon (Si) ≤1.0%, Phosphorus (P) ≤0.03%, and Sulfur (S) ≤0.01%12.

Physical & Mechanical Properties:

- Density: 8.0 g/cm³

- Tensile Strength: ≥690 MPa

- Yield Strength: ≥310 MPa

- Elongation: ≥30%

- Hardness: ≤220 HB

Product Performance Highlights

Outstanding Corrosion Resistance:

- 4529 exhibits superior resistance to pitting, crevice corrosion, and stress corrosion cracking (SCC) in a wide range of corrosive environments, including chlorides, sulfuric acid, and high-temperature solutions12.

- The high molybdenum content provides enhanced resistance to localized corrosion, making it ideal for severe corrosive conditions12.

Excellent Mechanical Properties:

- High tensile and yield strengths ensure that 1.4529 can withstand heavy loads and mechanical stress12.

- Good ductility and toughness allow for easy forming and machining12.

Good Weldability & Fabricability:

- 4529 can be easily welded using standard welding methods, producing strong and reliable joints12.

- It can also be forged, machined, and fabricated into various shapes and sizes12.

Production Methods

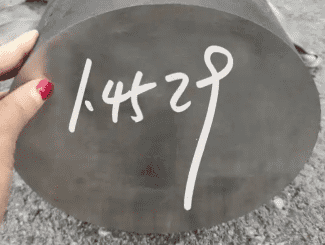

1.4529 round bars are manufactured through a precise and controlled process to ensure high quality:

- Raw Material Preparation: High-purity raw materials are selected and prepared for melting1.

- Melting & Casting: The raw materials are melted in an electric arc furnace (EAF) or vacuum induction melting (VIM) process to ensure a homogeneous alloy composition1.

- Hot Rolling: The molten metal is cast into ingots, which are then hot rolled into round bars of the desired diameter1.

- Heat Treatment: The hot-rolled bars undergo solution annealing and quenching to optimize their microstructure and mechanical properties1.

- Finishing: The bars are then sawed, turned, ground, and polished to meet customer specifications1.

Equivalent Grades & Standards

- UNS N08926

- DIN 1.4529

- ASTM B625, ASTM A240, ASTM B673, ASTM B674, ASTM B677

- Al-6XN, X1NiCrMoCuN25-20-7, 00Cr20Ni24Mo6N

- Incoloy 926, Alloy 926

Key Application Fields

1.4529 round bars are ideal for applications requiring exceptional corrosion resistance and mechanical strength:

- Chemical Processing: Reactors, heat exchangers, and piping systems handling corrosive chemicals and acids12.

- Petrochemical Industry: Equipment exposed to harsh environments and corrosive media12.

- Marine Engineering: Ship structures, desalination plants, and seawater systems12.

- Power Generation: Components in fossil fuel and nuclear power plants exposed to high-temperature and corrosive environments12.

- Pharmaceuticals: Equipment in contact with corrosive drugs and chemicals12.

- 4529 Round Bar Supplier

- UNS N08926 Corrosion-Resistant Alloy

- Super Austenitic Stainless Steel Round Bar

- 4529 vs 316L Stainless Steel

- Marine-Grade 1.4529 Rod

- Petrochemical Industry 1.4529 Applications

- ASTM B625 1.4529 Round Bar

1.4529 round bars offer unparalleled corrosion resistance and mechanical properties, making them the ideal choice for demanding applications in various industries. For more information or to place an order, contact a reputable supplier specializing in premium stainless steel alloys.