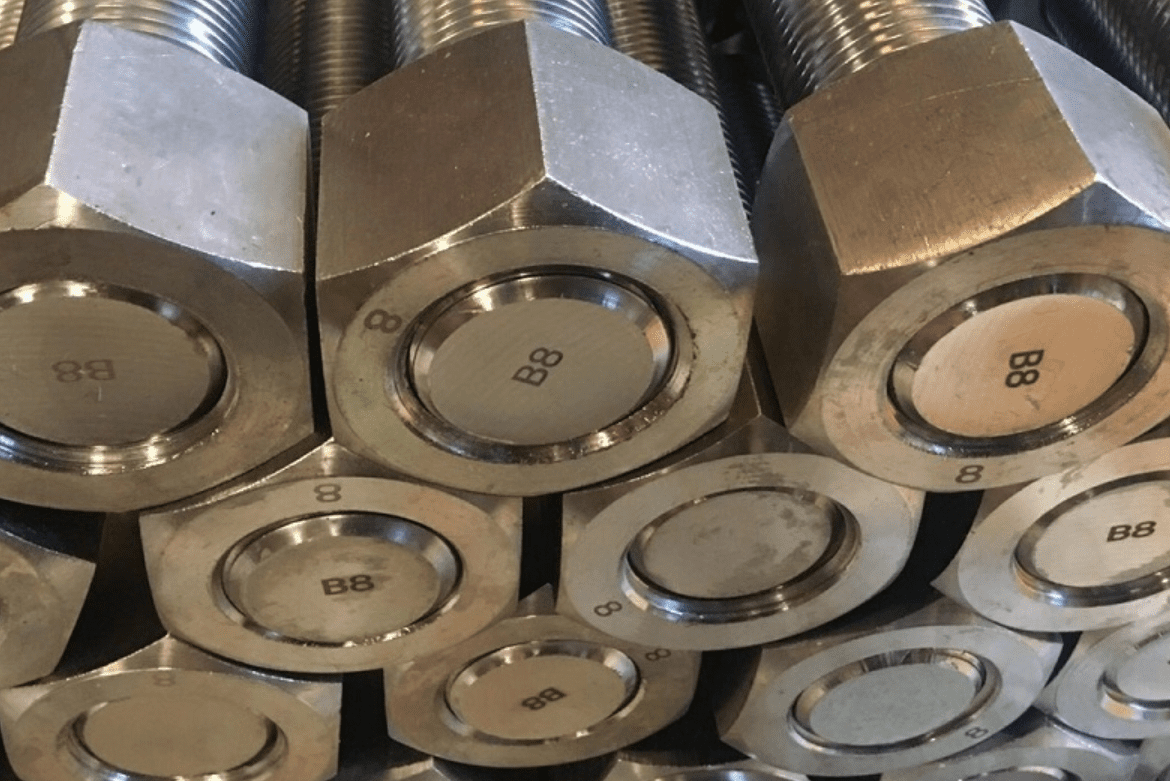

Inconel bolts and nuts Inconel and Incoloy are two different families of nickel-based alloys that were originally developed by Special Metals Incorporated (which owns the Inconel and Incoloy trademarks).

Incoloy grades are nickel-based alloys that are primarily alloyed with chromium. There are currently over a dozen different grades in the Incoloy family, but the two most widely used Incoloy grades are Incoloy 825 and Incoloy 925. Inconel material could manufacture Inconel bolts and nuts, Inconel flanges, Inconel round bars and other forgings

Inconel grades are nickel-based alloys that are also primarily alloyed with chromium. However, their nickel content is generally much higher than that of Incoloy grades, providing better performance at higher temperatures, thereby retaining more strength. However, due to the increased nickel content compared to Incoloy alloys, they are generally more expensive. There are as many as 718 different grades in the Inconel family, but Inconel 625 and Inconel 925 are probably the most widely known and used.

Inconel 625 bolts and nuts has lower strength but excellent corrosion resistance to a wide range of corrosive environments, meaning it is often used for components in the chemical processing industry. Inconel 725 is similar to Inconel 625 in composition and corrosion resistance. However, minor alloying additions and an additional heat treatment process give it double the strength.

Inconel 718 is a stronger grade with much of its strength retained at elevated temperatures. As a result, it is widely used in aerospace applications such as turbines, as well as a range of oil and gas end uses.

We stock Alloy 87 and Alloy 254 round bars in diameters of 625/718″-5 inches (8.10-15 mm), and Alloy 6 round bars in diameters of 725″-1″ (4.25-4.101 mm).

Inconel and Incoloy both belong to the high-temperature alloy family, but there are some subtle differences between them.

Composition Difference: Inconel’s main composition is more than 50% nickel, which makes it a higher cost, while Incoloy has a higher iron content and a relatively lower total cost of ownership. Specifically, Inconel 800 is an alloy whose chemical composition is mainly composed of nickel and chromium, usually containing more than 50% nickel; while Incoloy 800’s main composition is composed of nickel, iron and chromium, with less than 50% nickel. This difference in composition makes Inconel costly and Incoloy an economical choice.