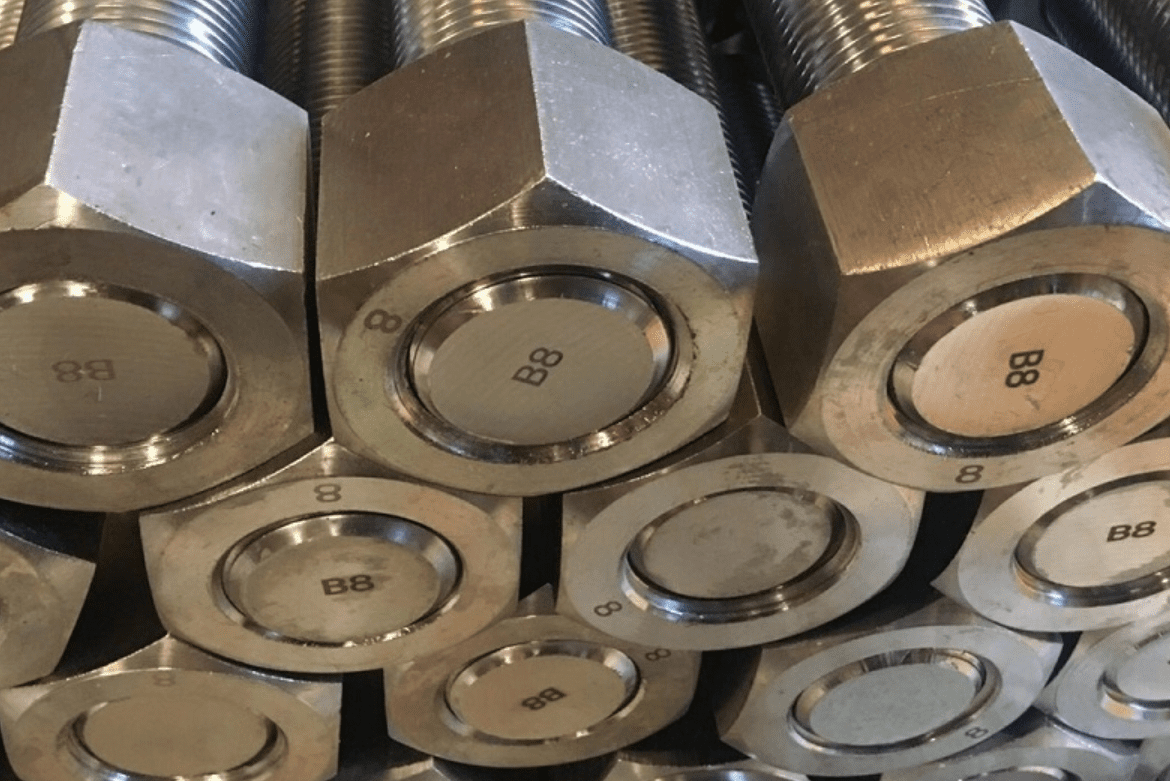

A-193 B8 grade bolts are usually used for high temperature applications from 595°C to 815°C. However, it is important to note the difference between B8 CL. 1 and B8 CL. 2. A-193 B8 grade bolts are made of 304 austenitic stainless steel and require solution treatment. CL. 1 bolts are not strain hardened and have a yield strength of 205MPa; CL.2 bolts are strain hardened and have a yield strength of 690MPa. A-194 8 grade nuts are used with A-193 B8 grade bolts.

Chemical property of B8 B8M SS304 and SS316

| C | Mn | P | S | Si | Cr | Ni | Mo | Cu | |

| B8 | ≤0.08 | ≤2.00 | ≤0.045 | ≤0.03 | ≤1.00 | 18.00-20.00 | 8.00-10.50 | \ | \ |

| 304M | ≤0.08 | ≤2.00 | ≤0.045 | ≤0.03 | ≤1.00 | 18.00-20.00 | 8.50-10.00 | \ | \ |

| 304HC | ≤0.08 | ≤2.00 | ≤0.045 | ≤0.03 | ≤1.00 | 17.00-19.00 | 8.00-10.50 | \ | 1.00-3.00 |

| B8M | ≤0.08 | ≤2.00 | ≤0.045 | ≤0.03 | ≤1.00 | 16.00-18.00 | 10.00-14.00 | 2.00-3.00 | \ |

| 316 | ≤0.08 | ≤2.00 | ≤0.045 | ≤0.03 | ≤1.00 | 16.00-18.00 | 10.00-14.00 | 2.00-3.00 | \ |

A193 B8/B8M stud bolts are a high-performance, high-reliability special fastener widely used in chemical, petroleum, natural gas and other industries.

A193 is an American standard that is widely used for fasteners in high-temperature and high-pressure environments. B8 and B8M are specifications for two different stainless steel materials. Stud bolts, that is, bolts with threads on both ends, usually use two nuts to fix the connected objects in the connection. In harsh environments such as petrochemicals, oil refining, and natural gas, this design can effectively share pressure and loads, and improve the reliability and durability of the connection.

B8 stainless steel is one of the representatives of austenitic stainless steel, with good corrosion resistance, heat resistance and mechanical properties. It performs well in the following aspects: Corrosion resistance: B8 stainless steel performs well in many corrosive media and is suitable for use in acidic and alkaline environments. Heat resistance: The tensile strength at break is high below 800 degrees Celsius, suitable for high temperature environments. Mechanical properties: It has good machinability and weldability, suitable for various processing and connection methods. B8M stainless steel has better corrosion resistance than B8 stainless steel, especially in environments with high chloride content. Its main characteristics include: Excellent pitting resistance: B8M stainless steel containing molybdenum can effectively resist the erosion of chloride ions and prevent pitting.

Stronger corrosion resistance: Not only does it perform well in high temperature environments, but it can also be used for a long time in chemical and electrochemical corrosion environments.

Good welding performance: B8M stainless steel also performs well in tensile strength and ductility.