Alloy59 is a nickel-based high-temperature alloy with excellent high-temperature and corrosion resistance, suitable for aerospace, petrochemical and other fields. It contains chromium, nickel, molybdenum and other elements, and has the characteristics of low magnetism, oxidation resistance,

high-temperature stability, and good processing and welding performance.

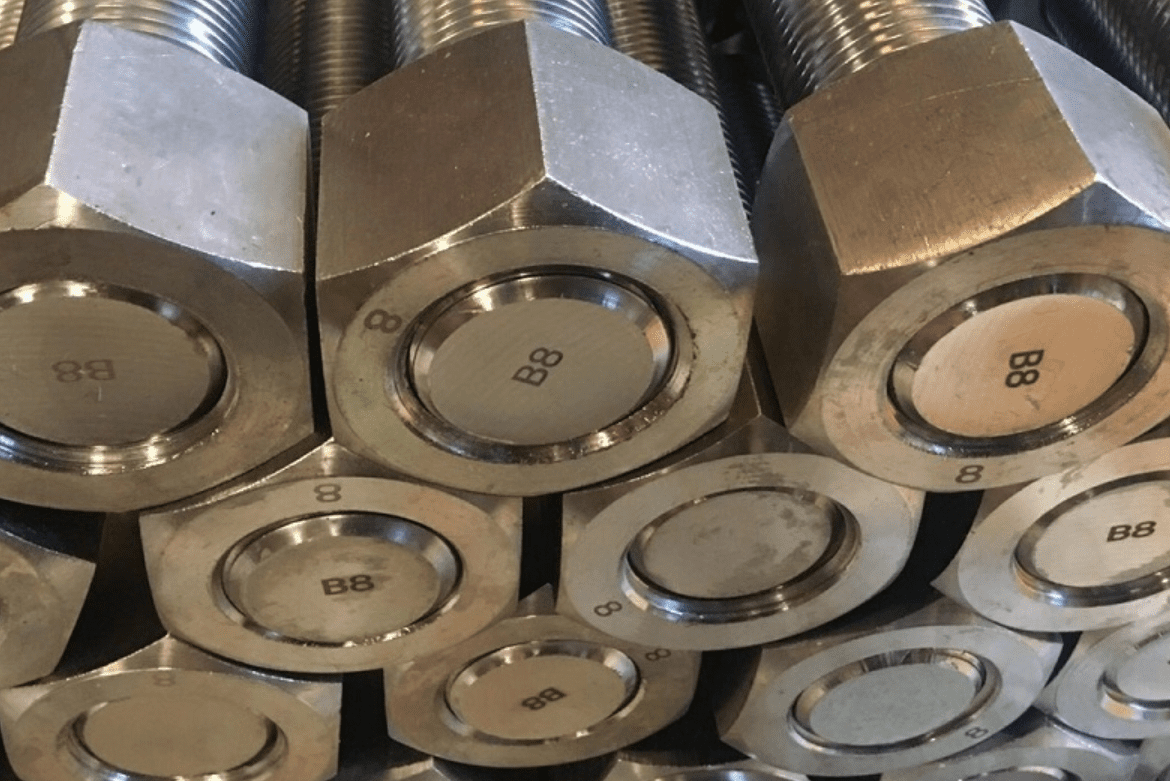

Alloy 59 Bolts, Alloy 59 Nuts, UNS N06059 Fasteners, 2.4605 Fasteners. Alloy59 screws Alloy59 round bars

- Standard-Based: ASTM F468 Alloy 59 Bolts, ASTM F467 Alloy 59 Nuts, EN 10204 3.1 Certified Fasteners.

- M5 to M100 Alloy 59 Bolts, 1/4” to 4” Alloy 59 Hex Bolts, Coarse and Fine Thread Alloy 59 Nut ,Alloy59 thread rod, Alloy59 stud bolts

- Alloy 59 Hex Head Bolts, DIN 933 Alloy 59, DIN 912 Alloy 59 Socket Cap Screws, Alloy 59 Stud Bolts

- Alloy 59 Fastener Manufacturer

- UNS N06059 Bolts Price 2026

- Buy 2.4605 Nuts Online

- Custom Alloy 59 Machined Fasteners

- Excellent resistance to pitting corrosion, crevice corrosion and chloride-induced stress corrosion cracking.

- Excellent corrosion resistance to inorganic acids, such as nitric acid, phosphoric acid, sulfuric acid and hydrochloric acid, especially to the mixture of sulfuric acid and hydrochloric acid.

- Excellent resistance to corrosion by various inorganic acid mixed solutions.

- Good corrosion resistance in hydrochloric acid solutions of various concentrations up to 40°C (104°F).

- Good machinability and weldability, no post-weld cracking sensitivity.

- Certified for the manufacture of pressure vessels with wall temperatures between -196 and 450°C.

- Certified by the American Association of Corrosion Engineers NACE standard (MR-01-75) to meet the highest standard level VII for use in sour gas environments.

- Marine & Seawater: Corrosion-resistant Seawater Fasteners, Alloy 59 Marine Grade Bolts, Offshore Fasteners UNS N06059.

- Chemical Processing: Flue Gas Desulphurization Fasteners, Sulfuric Acid resistant Bolts, Chemical Industry Nuts and Bolts.

- Oil & Gas: Sour Gas Handling Fasteners, NACE MR0175 Alloy 59 Fasteners, High Strength Subsea Bolts.

Corrosion resistance

Alloy59 can maintain stable performance in strong corrosive media such as acids, alkalis, chlorides, etc., and has the advantage of long service life. At the same time, it also shows good resistance to pitting and boiling corrosion, and can be used for a long time in high temperature and high relative humidity environments.