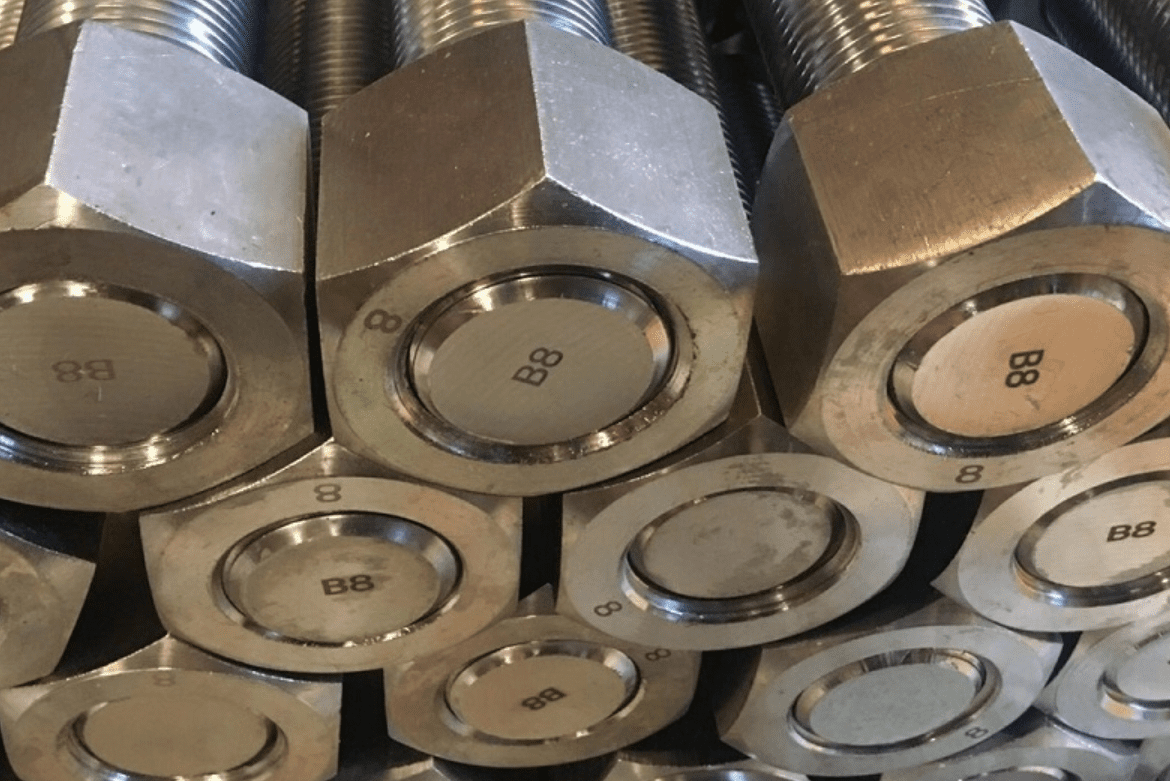

Alloy 20 is an austenitic stainless steel with resistance to sulfuric acid corrosion, stability, excellent mechanical properties and easy fabrication. Contains niobium to reduce welding carbide precipitation. Used in rubber, gasoline, chemical processing, etc. It has specific mechanical properties and can be cold rolled to meet tempering requirements. Surface treatment includes ultra-clean, grea

Alloy20 is an austenitic stainless steel with excellent resistance to sulfuric acid attack and many other corrosive environments. Alloy 20 CB-3 stainless steel also has stability to limit intergranular attack even under sensitized conditions. Important advantages of Alloy 20 CB-3 stainless steel are its excellent mechanical properties and relative ease of fabrication. The presence of niobium in the alloy minimizes the precipitation of carbides during welding.

Applications

Components for synthetic rubber processing

Gasoline,

Solvents,

Explosives,

Plastics,

Synthetic fibers,

Components for chemical processing

Food and dye production

Pharmaceutical processing components

Mechanical Properties at Room Temperature

Features: Annealed

Ultimate Tensile Strength: 80 KSI min (551 MPa min)

Yield Strength (0.2% deflection): 35 KSI min (241 MPa min)

Elongation: 30% min (Specifications: >0 .015 in.)

Hardness: Rb 95 max < strong>Features: Tempered

Alloy 20 CB-3 may be cold rolled to achieve the desired temper properties for specific

customer and/or manufacturing requirements.

lloy 20 is a nickel-chromium-iron alloy, mainly with added elements such as molybdenum and copper to enhance its corrosion resistance in acidic environments. Its main performance characteristics include:

Excellent corrosion resistance: especially in sulfuric acid, chloride and other corrosive media.

Good weldability: can be processed by a variety of welding methods, easy to manufacture and repair.

Excellent mechanical properties: can still maintain high strength and toughness at different temperatures.

Alloy 20 is widely used in petrochemical, pharmaceutical, food and marine engineering. Its excellent acid resistance makes it an ideal choice for manufacturing reactors, pipelines, heat exchangers and other equipment.